Precision customized lightweight heat-resistance stable fast magnetic response Epoxy-Coated Custom Green Magnets are designed to meet the evolving demands of modern industries—combining innovative shape flexibility, robust protective coating, and powerful magnetic force in one elegant solution.

Custom-Shaped lightweight high stability fast magnetic response small Epoxy-Coated Green Magnet

1. Product Overview & Application Scenarios

Precision customized lightweight heat-resistance stable fast magnetic response Epoxy-Coated Custom Green Magnets are designed to meet the evolving demands of modern industries—combining innovative shape flexibility, robust protective coating, and powerful magnetic force in one elegant solution.

√ Tailor-Made for Innovation

Manufactured with precision, these magnets feature non-standard geometries to perfectly fit complex assemblies—eliminating design constraints and improving product efficiency.

√ Advanced Epoxy Protection

The durable green epoxy coating provides excellent resistance against corrosion, chemicals, and humidity, ensuring long-lasting performance even in the harshest environments.

√ High Magnetic Performance

Built with high-grade magnetic materials, our magnets offer strong, consistent pull force, making them ideal for compact and high-efficiency devices.

Application Fields:

Industrial Automation & Robotics

Applications: Robotic arms, grippers, end-effectors, precision alignment tools.

Benefits:

Custom shapes integrate seamlessly into complex mechanical assemblies

Protective coating resists dust, oil, and humidity in harsh environments

Improves repeatability, positioning accuracy, and operational reliability

Consumer Electronics & Smart Devices

Applications: Magnetic attachments, wireless charging modules, wearables.

Benefits:

Sleek, thin magnet design suits compact electronics

Custom shapes enable hidden and aesthetic integration

Eco-friendly epoxy coating meets international safety standards

Automotive Electronics

Applications: Electric seats, power liftgates, window motors, ABS feedback systems.

Benefits:

Withstands high temperatures and engine compartment conditions

Consistent magnetic performance meets automotive-grade requirements

Enhances actuator responsiveness and system durability

2. Technical Specifications

Product Name:Custom-Shaped lightweight high stability fast magnetic response small Epoxy-Coated Green Magnet

Magnet Grade: N45 (Br ≥ 14.8 KGs, Hcj ≥ 10.5 KOe) — Customizable

Dimensions: L12 x 10×3 mm

Tolerance: ±0.05 mm (Length, Width, Thickness)

Operating Temperature: ≤ 80°C (Customizable high-temp versions available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2400 Gauss (Measured using Japan TM-801 Gauss meter)

Magnetic Flux: 2.2 mWb (Measured; value varies by material grade)

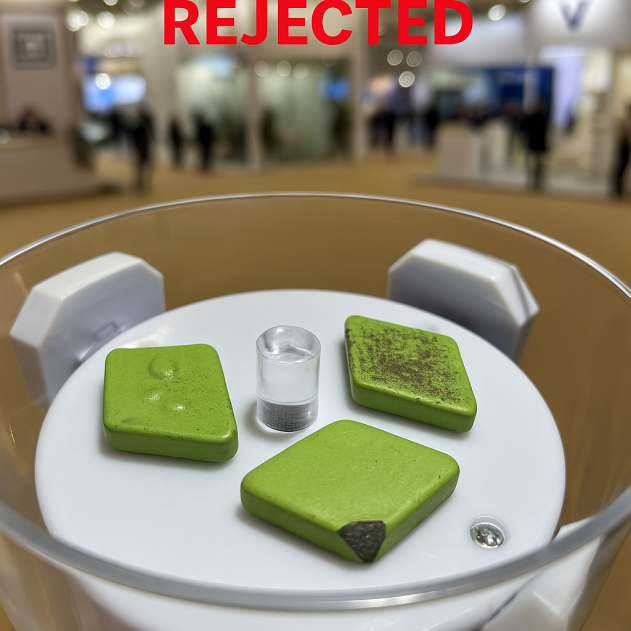

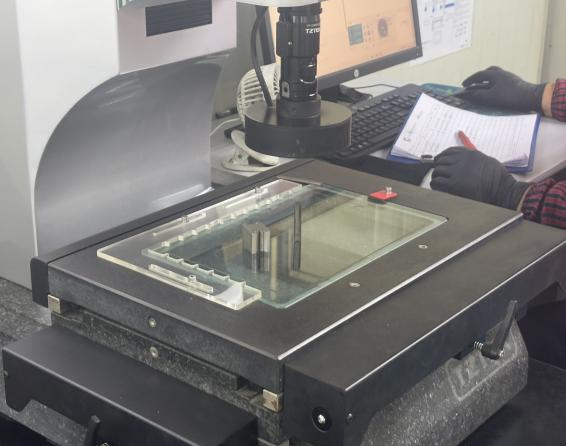

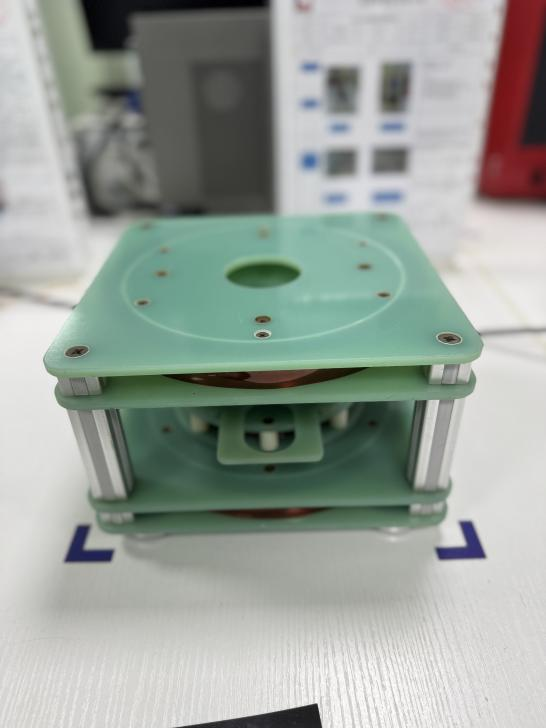

3. Appearance & Dimensional Inspection

The inspection ways of this customized lightweight fast magnetic response high stability corrosion resistance small epoxy coated magnet are as follows:

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Image Measurement System: High-res cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

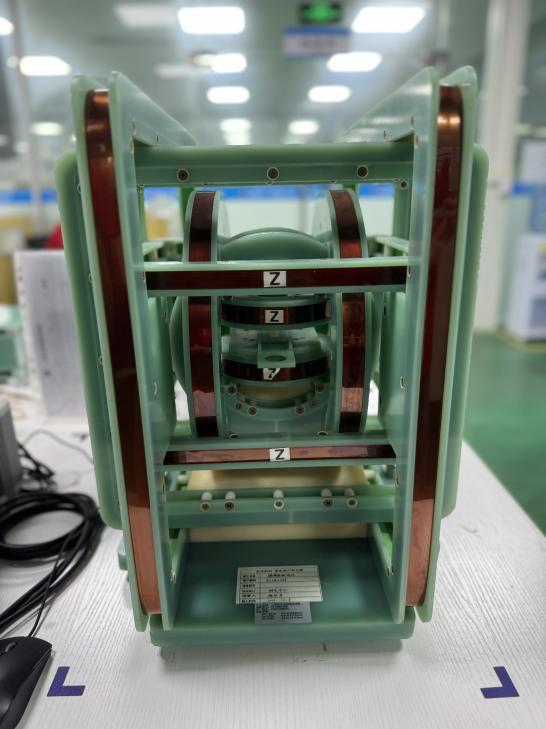

Magnetic Flux Consistency Test: Fluxmeters or Hall-effect testers measure magnetic flux across batches to ensure uniform performance in end-user applications

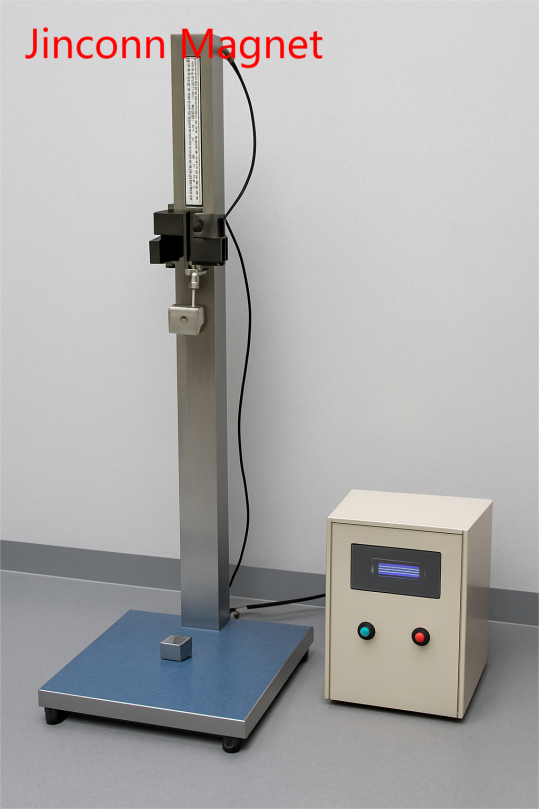

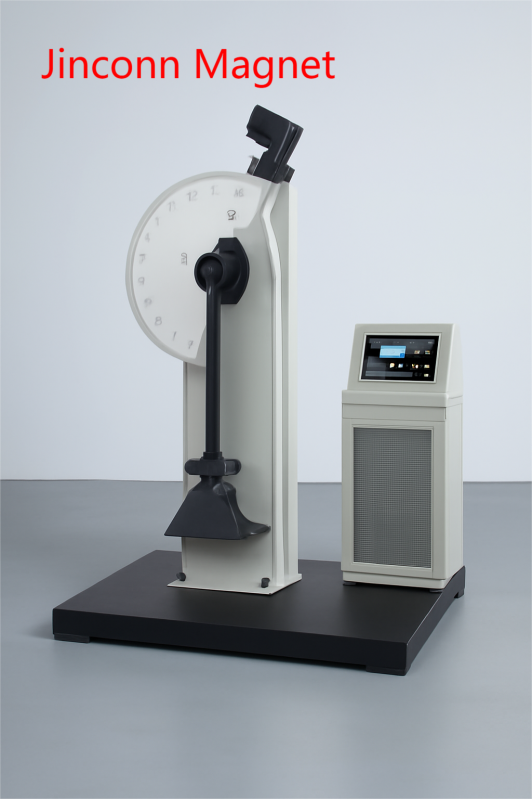

4. Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

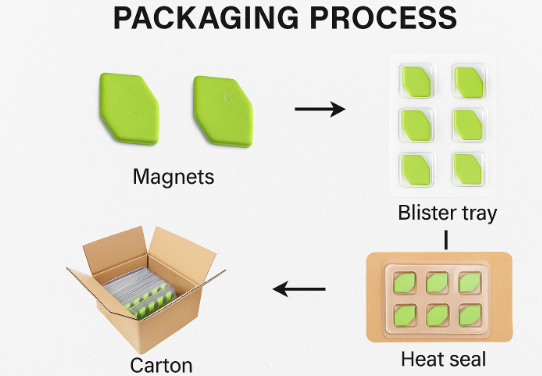

5.Packaging & Transportation

Quality Control: Every magnet undergoes 100% inspection using calipers, projectors, and automated systems to ensure no defects like cracks, chips, oxidation, or coating issues.

Optimal Magnetization & Packaging: Magnets are evenly magnetized and arranged for efficient packaging and easy automation, tailored to your needs for top performance.

Advanced Packaging: Our multi-layer vacuum packaging, with moisture barriers and desiccants, protects against corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shockproof, moisture-resistant, and anti-magnetic leakage packaging meets international standards, complete with product lists, labels, and tracking codes for easy handling.

At the heart of logistics is more than just movement — it's about delivering on your promises and ensuring customer satisfaction. Our comprehensive solutions provide:

Global logistics coverage to keep you connected everywhere.

Real-time visual tracking for complete transparency at every stage.

Multi-layered security for safe, reliable transport.

Personalized customer service with customized shipping plans tailored to your needs.

With our trusted land, sea, and air network, we help your business reach new heights and expand globally, every step of the way.

6. FAQ

Q. What is an epoxy-coated magnet and why is it used?

Epoxy coating protects magnets from corrosion, chemical exposure, and physical wear, especially in humid or harsh environments. It's ideal for applications requiring durability and stability.

Q. What shapes and sizes can be customized for epoxy-coated magnets?

We support a wide range of custom shapes—trapezoid, arc, wedge, rhombus, and more. Dimensions can be tailored based on your application and tolerances.

Q. How strong are epoxy-coated magnets compared to other coatings?

Epoxy-coated magnets maintain the same core magnetic strength as uncoated magnets. The coating enhances durability without compromising performance.

Q. Are epoxy-coated magnets suitable for high-temperature applications?

Yes, we offer temperature-resistant grades suitable for up to 200°C. Let us know your operating conditions so we can recommend the right material grade.

7. Why Choose us ?

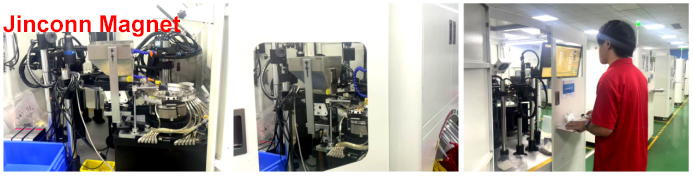

At JinConn, we are committed to delivering high-performance magnetic products and customized services that help our clients gain a competitive edge. Here’s why industry leaders choose us:

✅ Rich Industry Experience

With over a decade of expertise in magnetic materials and precision magnet manufacturing, we understand the technical demands of a wide range of industries.

✅ Strong R&D and Customization Capabilities

Our in-house engineering and tooling teams enable us to offer custom-shaped, high-precision, and application-specific magnets tailored to your unique requirements.

✅ Certified Quality Assurance

We adhere to international standards including ISO 9001, ISO 14001, and IATF 16949, with strict quality control from raw materials to finished products.

9. Usage Precautions?

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10. Customization & Services

· Customized Magnet Sizes, Shapes, and Coatings: We offer fully tailored magnet dimensions, shapes, and coating options, including multiple layers, varying thicknesses, and color choices.

· Personalized Magnetization & Strength: Magnetization direction and field strength can be adjusted to meet your specific application requirements.

· Laser Engraving: We provide laser engraving services for logos, serial numbers, or other custom markings.

· Specialized Testing: We conduct packaging and suction force testing to ensure performance in unique or demanding applications.

Contact us to receive free samples and customized magnet solutions

Phone/WhatsApp/WeChat: +86 13829120676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat