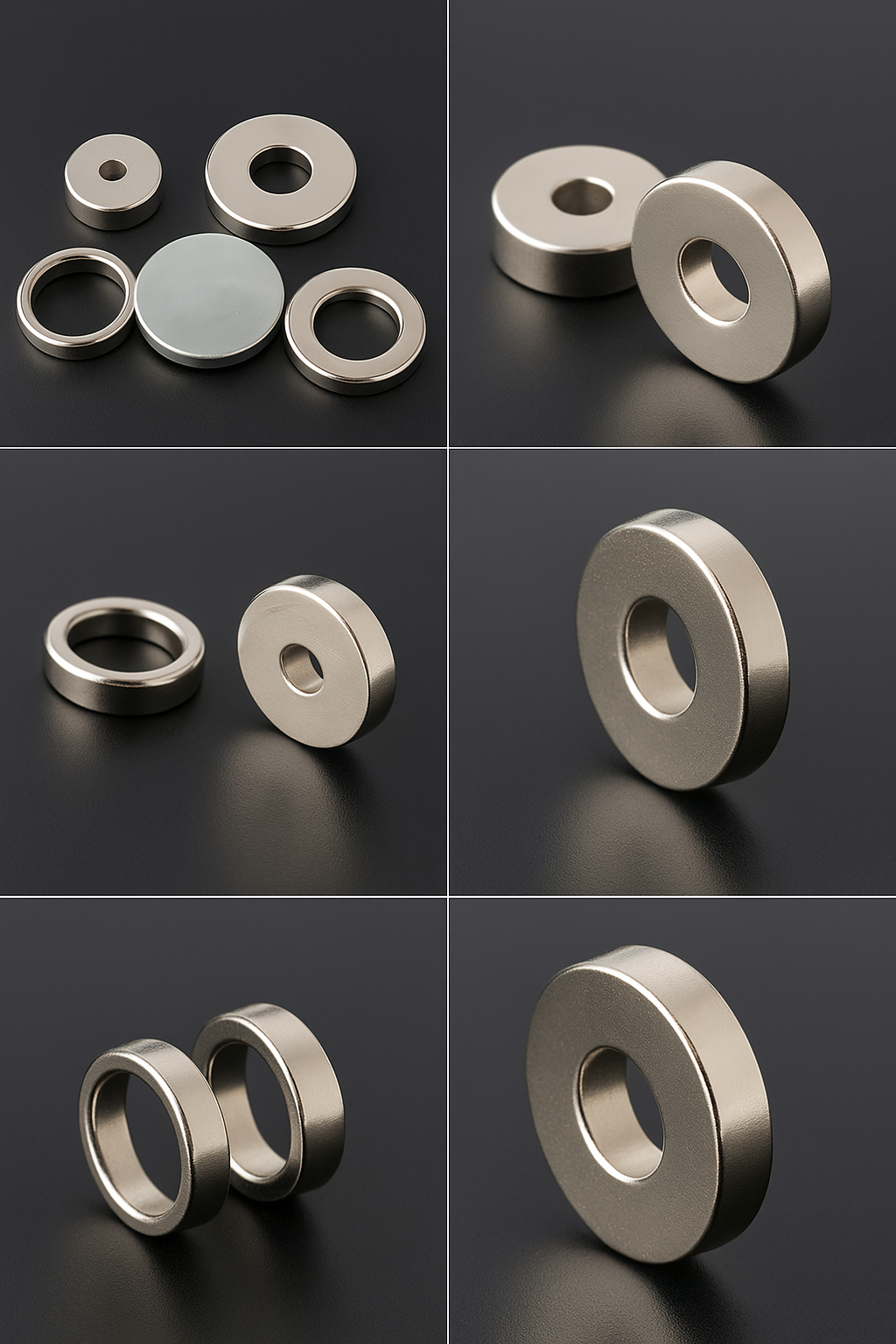

High adhesive force corrosion resistance stable small round Ndfeb Ring Magnets are rare earth permanent magnetic materials composed primarily of Neodymium (Nd), Iron (Fe), and Boron (B), manufactured via high-precision sintering processes.

High adhesive force small round ndfeb Ring Magnets

1. Product Overview

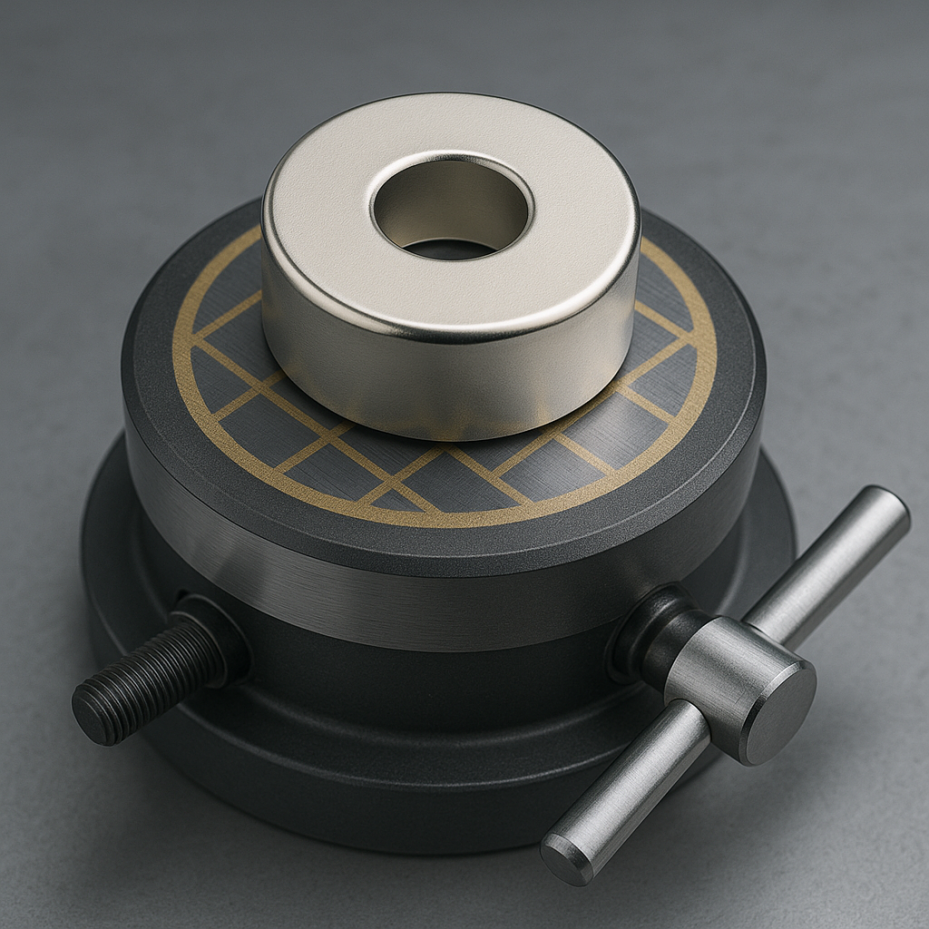

High adhesive force corrosion resistance stable small round Ndfeb Ring Magnets are rare earth permanent magnetic materials composed primarily of Neodymium (Nd), Iron (Fe), and Boron (B), manufactured via high-precision sintering processes. These magnets exhibit excellent magnetic properties, high energy product (BHmax), and structural diversity.

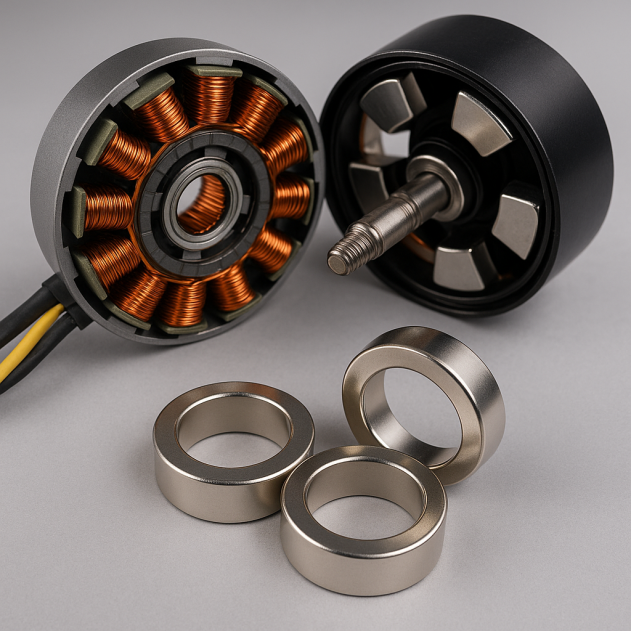

These customized heat-resistant high adhesive force small round ndfeb Ring Magnets are widely used in motors, sensors, speakers, medical devices, automation equipment, and renewable energy systems. The ring-shaped structure allows for easy assembly, controlled magnetic flux direction, and improved magnetic circuit efficiency—ideal for hollow mounting or axial magnetic field design applications.

2. Technical Specifications

Product Name: High adhesive force small round Ndfeb Ring Magnets

Magnet Grade: N40 (Br ≥ 13.2 KGs, Hcj ≥ 10.8 KOe)

Product Dimensions: D24-D12*2mm

Tolerance: Outer Diameter ±0.05mm, Inner Diameter ±0.05mm, Thickness ±0.05mm

Working Temperature: ≤ 80°C (customizable for high-temperature versions)

Density: ≥ 7.5g/cm³

Magnetic Field Strength (Surface Gauss): 2900 GS

Magnetic Flux Value: 2.9 mWb (measured with fluxmeter)

3. Manufacturing Process

• Thin-wall Anti-crack Technology: Ultrasonic-assisted cutting to reduce cutting stress; cryogenic processing to prevent material cracking.

Grain Boundary Diffusion Technology: Surface coating with dysprosium compounds to improve coercivity.

4 . Appearance and Dimensional Inspection Standards

To ensure this precision customized high adhesive force stable small round Ndfeb Ring Magnets’ quality consistency and reliability, all products undergo the following strict inspections:

• Visual Inspection under 800–1200 lumen lighting, 20–750px distance

2D Optical Measuring System for complex or non-standard structures

Magnetic Flux Testing to ensure consistency in magnetic performance across batches

5. Reliability Testing

• Salt Spray Test: Evaluates corrosion resistance of coating in salt mist environment

Tensile/Bonding Strength Test: Measures adhesive strength for glued or bonded applications to prevent detachment from vibration or aging

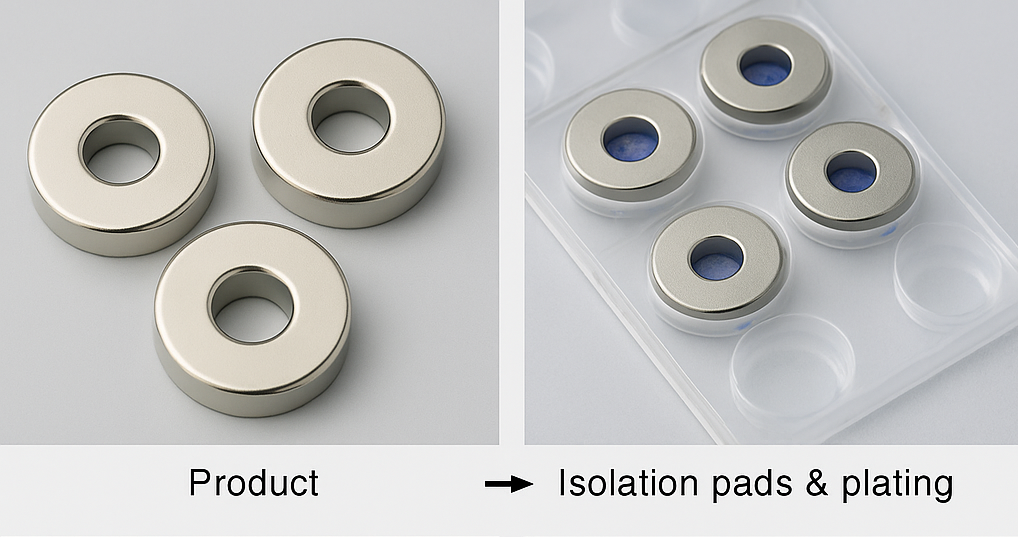

6. Packaging Process

In accordance with magnetic product transport requirements, we adopt professional packaging methods:

• Eliminate non-conforming items (appearance or dimensional defects)

• Magnetize and neatly arrange qualified products

• Box and label per customer requirement

• Vacuum packaging with anti-magnetic shielding and cushioning pads

• Inner boxes placed in outer cartons — moisture-proof, shock-proof, and anti-magnetic interference

• Custom packaging available

7. Application Fields:

Audio & Acoustic Equipment

Hi-Fi speakers, headphones, tweeters, buzzers

✅ Benefits:

Clearer Sound Reproduction: Strong magnetic fields ensure faster diaphragm response and lower distortion.

Greater Sensitivity: Improves acoustic fidelity and performance across frequency ranges.

Durability: Reliable magnetic force under high power and long-term use.

Magnetic Coupling & Mounting Systems

Magnetic drive pumps, couplers, chucks, alignment fixtures

✅ Benefits:

Contactless Torque Transmission: Enables sealed or isolated mechanical systems.

High Holding Force: Ensures stable positioning and reduced energy loss.

Eco-Friendly: No lubrication needed, low maintenance, silent operation.

Consumer Magnetic Accessories

Phone holders, magnetic fasteners, cabinet latches, wellness magnets

✅ Benefits:

Strong & Stable Holding Force: Ideal for repeated attachment/detachment.

Sleek Appearance: Smooth nickel finish supports modern consumer design aesthetics.

User-friendly Experience: Reliable magnetism, long service life, and safe performance.

8. Usage Precautions

• Temperature Limits: Avoid exceeding Curie temperature (310–340°C) to prevent irreversible demagnetization

• Brittleness: Avoid impact or interference fits

• Polarity Identification: Install based on correct pole orientation to ensure proper device operation

• Moisture and Corrosion Protection: Store away from high temperature, humidity, acids, and alkalis

• Keep Away from Sensitive Devices: Maintain safe distance from hard drives, IC cards, pacemakers, etc.

9. Customization and Services

We support a wide range of customization services:

• Dimensions, shape, coating (layers, thickness, color)

• Pole orientation and magnetic strength

• Laser logo engraving or serial number marking

• Encapsulation solutions and suction force testing for special applications

10. Why choose Jinconn magnet

Company Introduction:

Dongguan Jinconn New Material Holdings Co., Ltd. specializes in the research, development, production, and sales of high-performance magnetic materials. Adhering to the philosophy of “Technology as the foundation, quality as the soul,” the company is committed to becoming a global leader in magnetic material solutions. Its products are widely used in fields such as new energy vehicles, intelligent manufacturing, electronic communications, automation equipment, and medical devices, earning the trust of customers both at home and abroad. Looking ahead, the company will continue to be driven by customer needs, promote technological innovation and industry integration, support the development of the global intelligent industry, and strive to become a benchmark enterprise and trusted strategic partner in the magnetic materials industry.

We are dedicated to providing high-performance magnetic material solutions for industries such as new energy vehicles, intelligent manufacturing, and electronic communications. Backed by advanced technology and rigorous quality standards, we are a trusted partner to leading companies worldwide.

We are pleased to offer free customized magnet solutions tailored to your specific needs.

Contact Us:

Phone: +86 138 2912 0676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat