Industrial grade special-shaped energy efficient high magnetic strength permanent rectangular ndfeb magnet is engineered for high-performance magnetic applications requiring precise form factors.

Custom-Shaped industrial grade high magnetic strength permanent rectangular ndfeb magnet

1. Product Description and Application Fields

Industrial grade special-shaped energy efficient high magnetic strength permanent rectangular ndfeb magnet is engineered for high-performance magnetic applications requiring precise form factors. Crafted from premium NdFeB (Neodymium-Iron-Boron) material, this precision customized professional grade corrosion resistance high magnetic strength permanent rectangular ndfeb magnet offers exceptional magnetic strength within a compact, sleek body. Designed with smooth edges and optional chamfers or grooves, it is ideal for specialized assemblies or embedded systems.

2. Technical Specifications

Product Name: Custom-Shaped industrial grade high magnetic strength permanent rectangular ndfeb magnet

Magnet Grade: N48 (Br ≥ 14.8 KGs, Hcj ≥ 10.5 KOe) — Customizable

Dimensions: 25mm × 5mm × 8mm

Tolerance: ±0.05 mm (Length, Width, Thickness)

Operating Temperature: ≤ 80°C (Customizable high-temp versions available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 4300 Gauss (Measured using Japan TM-801 Gauss meter)

Magnetic Flux: 2.0 mWb (Measured; value varies by material grade)

3. Surface Treatment & Coating Technology

- Laser Cladding:

Nickel-based alloy fusion at edges → Enhanced hardness

- Cleaning & Degreasing:

Ultrasonic cleaning with alcohol/specialized solvents

- Activation Treatment:

Immersion in dilute HCl/H₂SO₄ → Improved coating adhesion

4.Appearance and Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

Magnetic Flux Consistency Test: Fluxmeters or Hall-effect testers measure magnetic flux across batches to ensure uniform performance in end-user applications.

5. Reliability Testing

This precision customized professional grade heat resistance high magnetic strength permanent rectangular ndfeb magnet through the following reliability tests :

Magnetic Performance:

- Field strength mapping (Gauss meter)

- Stability under thermal/humidity aging

Physical Properties:

- Hardness (Rockwell/Vickers testers)

- Density measurement

- Dimensional accuracy (micrometer/caliper)

Environmental Adaptability:

- Temperature cycling: -40°C to +80°C

- Humidity: >90% RH exposure

6. Packaging & Transportation

Defect Elimination:

100% inspection using calipers, projectors, visual checks, and automation to reject magnets with cracks, chips, oxidation, or coating defects.

Consistent Magnetization & Arrangement:

Magnets are uniformly magnetized and arranged per customer requirements to ensure performance and enable automated assembly.

Vacuum Packaging:

Multi-layer vacuum sealing with moisture barriers, desiccants, or nitrogen prevents corrosion and magnetic interference during storage and transport.

7. FAQ

Q.Will the magnet lose its magnetism over time?

Under normal conditions (avoiding overheating or mechanical shock), neodymium magnets retain their magnetism for decades. Exposure to high temperatures (above 80°C for some grades) can cause irreversible demagnetization.

Q.Can I use these magnets for magnetic therapy or health purposes?

While magnetic therapy is a popular topic, no conclusive scientific evidence supports health benefits from permanent magnets. Use with caution and avoid placing near pacemakers or other medical implants.

8. Why Choose Us ?

Industry Expertise & Innovation

Over 20 Years of Experience in the rare earth permanent magnet industry.

Specialized in NdFeB magnet manufacturing, with customized solutions for demanding applications.

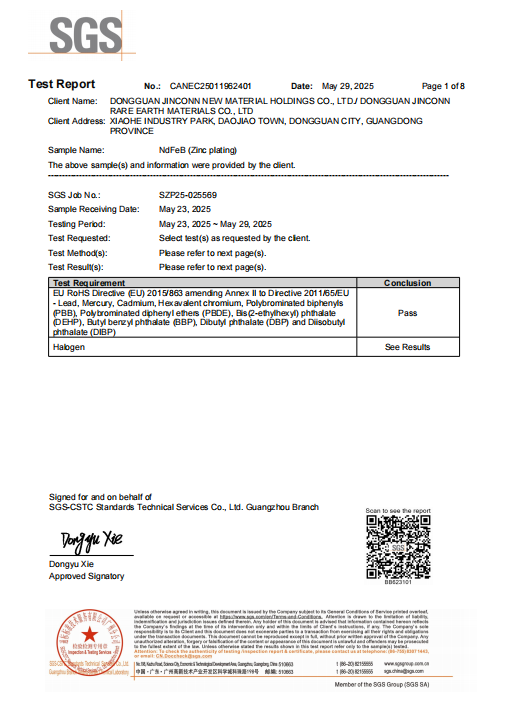

Strong R&D capabilities, including close collaboration with universities and independent lab testing.

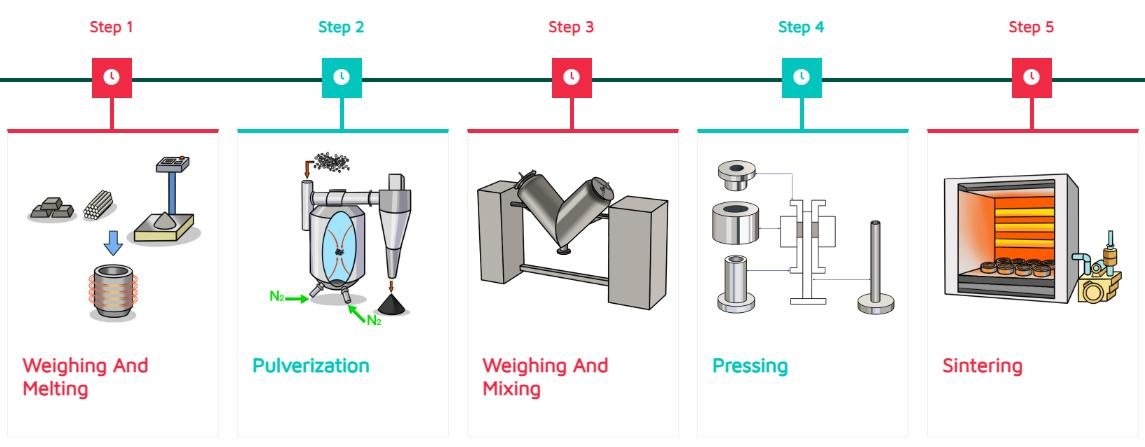

Advanced Production Capabilities

Fully equipped modern manufacturing facility in Dongguan, covering [insert area if available, e.g. 5,000+ m²].

Equipped with precision cutting, coating, and inspection lines.

Full process control from raw material selection to final surface treatment, ensuring stability and high-quality yield.

Customer-Centric Customization

Capable of designing magnets based on customer drawings or performance specs.

Supports low-volume prototypes and large-scale production.

Offers technical consultation to support integration into final products.

9. Usage Precautions

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10.Customization & Services

Custom magnet size, shape, and coating (layers, thickness, color)

Tailored magnetization direction and field strength

Laser engraving service for logos or serial numbers

Packaging and suction force testing for special applications

Magnetic Solutions That Move Your World

If you have any magnet-related needs, we offer free customized magnet services. Please feel free to contact us at any time.

Contact Us:

Phone/WhatsApp/WeChat: +86 13829120676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat