Arc Segment Neodymium Magnet for Motors — The Silent Power Behind Precision Motion

In the quiet lies its might. Within a seamless curve, this Precision customized high temperature resistance fast response strong rare earth stable nickel plated Arc Segment Permanent Magnet channels immense magnetic energy into a finely tuned force — a force that silently drives the future of motion.

Customized heat resistant strong rare earth stable nickel plated Arc Segment Permanent Magnet

1. Product Introduction & Application fields

Arc Segment Neodymium Magnet for Motors — The Silent Power Behind Precision Motion

In the quiet lies its might. Within a seamless curve, this Precision customized high temperature resistance fast response strong rare earth stable nickel plated Arc Segment Permanent Magnet channels immense magnetic energy into a finely tuned force — a force that silently drives the future of motion.

Crafted from premium rare earth materials (grades ranging from N35 to N52, or high-temperature options like SH and UH), this tailor made premium quality heat resistant strong rare earth stable nickel plated Arc Segment Permanent Magnet delivers an impressive energy product up to 52 MGOe. Engineered for excellence, its arc geometry fits rotor assemblies with surgical precision, ideal for BLDC motors, servo motors, and high-speed permanent magnet rotors.

Smart Robots & AGVs (Automated Guided Vehicles)

Role: Powers drive wheels and joint actuators for accurate navigation, balance, and intelligent mobility in robotics platforms.

Smart Home Appliances (e.g. robot vacuums, inverter compressors)

Role: Provides compact, durable magnetic force for quiet, energy-efficient, and long-life operation.

Brushless DC Motors (BLDC)

Role: Arc magnets form a tight magnetic circuit in the rotor, delivering high torque density and fast response. Ideal for drones, electric tools, and household appliances.

2. Technical Specifications

Product Name: Customized heat resistant strong rare earth stable nickel plated Arc Segment Permanent Magnet

Magnet Grade: N48 (Br ≥ 14.8 KGs, Hcj ≥ 10.5 KOe) — Customizable

Dimensions: D10-D12×4 mm

Tolerance: ±0.05 mm (Length, Width, Thickness)

Operating Temperature: ≤ 80°C (Customizable high-temp versions available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2400 Gauss (Measured using Japan TM-801 Gauss meter)

Magnetic Flux: 2.2 mWb (Measured; value varies by material grade)

3. Surface Treatment & Coating Technology

- High-Precision Bonding: The use of flexible epoxy adhesive enhances the bonding strength of the magnets.

-In-line Magnetic Field Compensation: During the assembly process, the magnetic field is measured in real time, and positional adjustments of the magnetic segments are made to compensate for deviations.

4. Appearance and Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

5. Reliability Testing

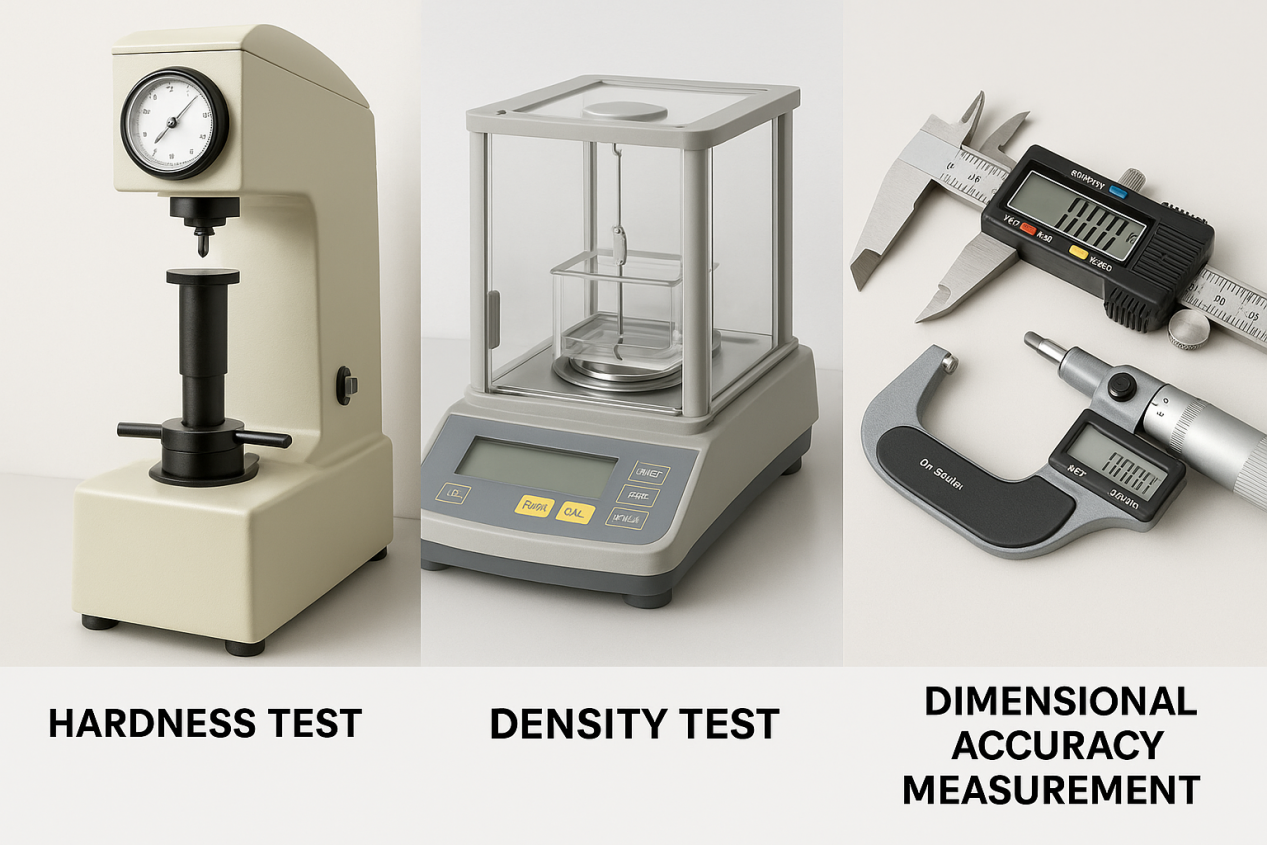

Physical Performance Testing:

- Hardness Test: Uses Rockwell or Vickers hardness testers to ensure wear resistance.

- Density Test: Evaluates structural uniformity and compaction via density measurement.

- Dimensional Accuracy Measurement: Ensures tolerances using calipers and micrometers.

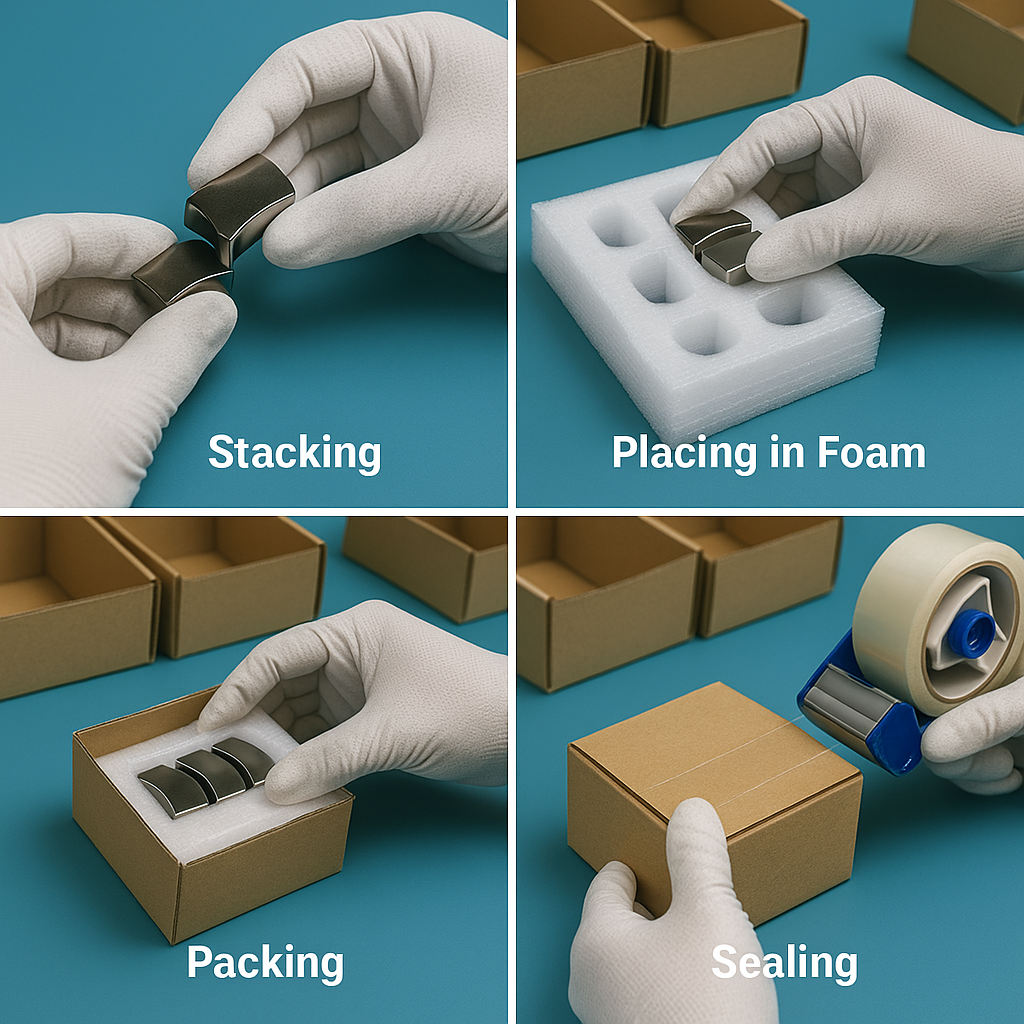

6. Packaging & Transportation

Defect Elimination:

100% inspection using calipers, projectors, visual checks, and automation to reject magnets with cracks, chips, oxidation, or coating defects.

Consistent Magnetization & Arrangement:

Magnets are uniformly magnetized and arranged per customer requirements to ensure performance and enable automated assembly.

Vacuum Packaging:

Multi-layer vacuum sealing with moisture barriers, desiccants, or nitrogen prevents corrosion and magnetic interference during storage and transport.

With our reliable land, sea, and air logistics network, we empower your business to go further and soar higher.

7. FAQ

Q.What is an arc segment magnet?

This customized heat resistant high coercivity strong rare earth stable nickel plated Arc Segment Permanent Magnet is a curved piece of magnet, typically made from neodymium (NdFeB), designed to fit around the inner diameter of motors. Its shape helps create a uniform magnetic field, making it ideal for use in brushless DC motors, servo motors, and generators.

Q.What is the maximum operating temperature of an arc magnet?

Depending on the grade, arc magnets can operate up to 80°C (standard) to 200°C (high-temp grades like UH/EH). It’s essential to match the grade with your motor’s thermal requirements.

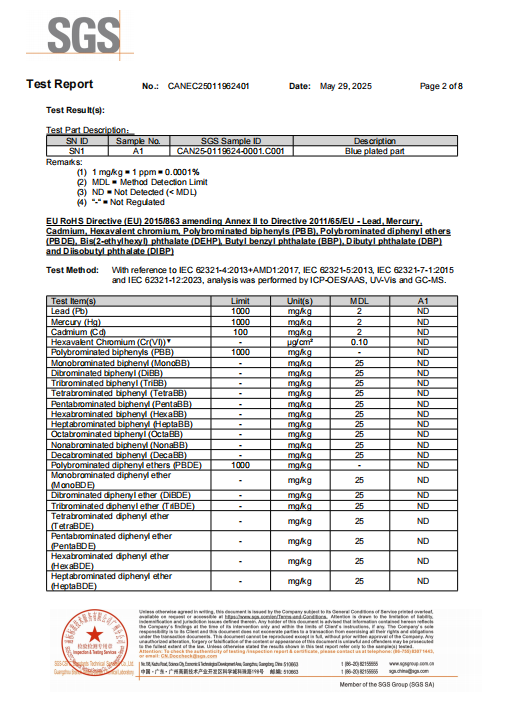

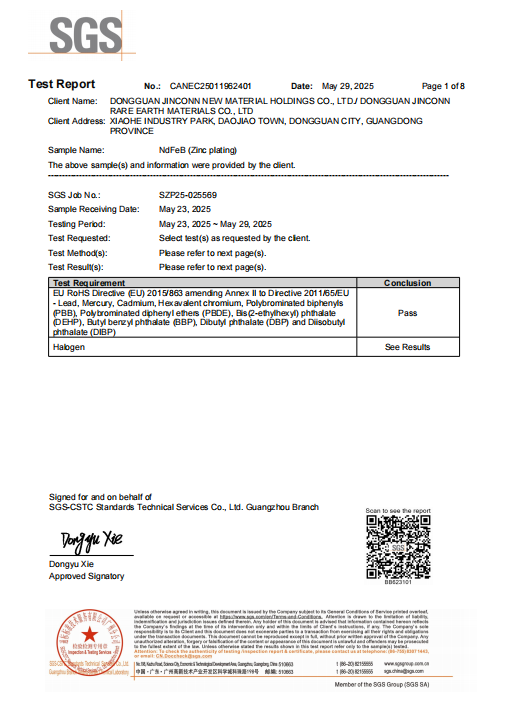

Q.Are your magnets RoHS and REACH compliant?

Yes. All our magnets meet RoHS and REACH standards. Compliance certificates can be provided upon request for international shipments and audits.

8. Why Choose Us ?

✅ 1. 20+ Years of Rare Earth Magnet Manufacturing Expertise

We have over two decades of experience in the development and production of high-performance Neodymium (NdFeB) magnets, serving industries such as motors, EVs, robotics, automation, wind energy, and smart appliances.

✅ 2. Complete Product Portfolio & Tailored Customization

From arc segments, blocks, rings, to complex-shaped magnets and magnet assemblies — we offer fully customized solutions based on your drawings, tolerance needs, magnetic orientation, and matching requirements.

✅ 3. High Magnetic Performance for Demanding Conditions

We provide magnets in grades from N35 to N52, including high-temperature grades like SH, UH, and EH, ensuring strong, stable magnetic performance even in high-speed, high-heat applications such as EV drive motors and wind turbines.

✅ 4. Strict Quality Control & Advanced Testing Equipment

Our production line includes automated sorting systems, Gauss meters, CMMs (Coordinate Measuring Machines), high-temperature aging testers, and more — guaranteeing precision in flux, dimension, and surface integrity.

9. Usage Precautions

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10.Customization & Services

Custom magnet size, shape, and coating (layers, thickness, color)

Tailored magnetization direction and field strength

Laser engraving service for logos or serial numbers

Packaging and suction force testing for special applications

We’re here to help!

Phone/WhatsApp/WeChat:+86 180 3822 5893

Email: info@jinconn.com

Website: www.jinconnmagnet.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat