This strong magnetic force stable compact segmented radial arc ndfeb magnet depends on how it's manufactured and paired

Compact Segmented Radial Arc NdFeB Magnet

1. Products Overview:

This strong magnetic force stable compact segmented radial arc ndfeb magnet depends on how it's manufactured and paired. It is shaped with a curved surface and appears to be precision-machined and possibly coated with Ni-Cu-Ni (nickel-copper-nickel) or another protective coating to prevent corrosion.

Magnet Type:

v Material: NdFeB (Neodymium Iron Boron)

v Grade (likely): N35–N52 depending on strength and heat resistance needs

v Shape: Arc or semi-elliptical block

v Coating: Likely nickel or epoxy for protection

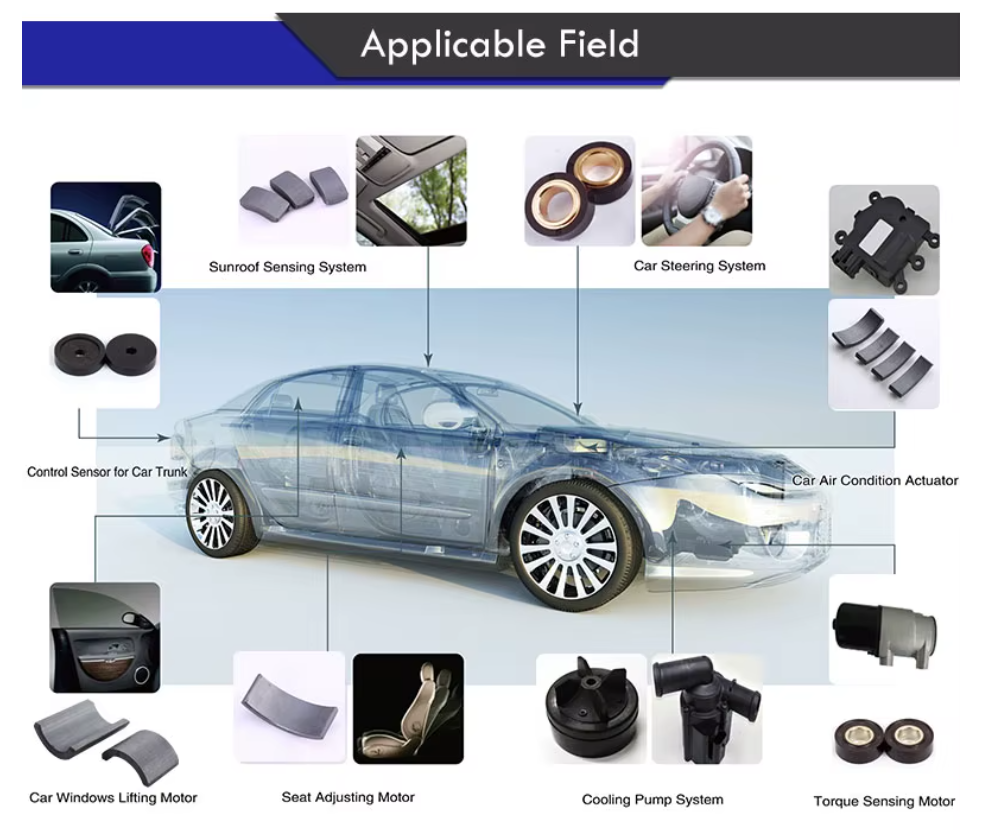

2. Common Application:

This heat resistant super strong magnetic force stable compact segmented radial arc ndfeb magnet characterized by their curved shape and strong magnetic properties, are widely used in various applications, particularly in electric motors and generators. They are also found in medical devices, robotics, and industrial automation equipment. Their ability to generate a strong magnetic field with a reduced air gap between the magnet and the stator contributes to improved motor performance.

2. Techinical Parameters

Product Name | strong magnetic force stable compact segmented radial arc ndfeb magnet |

Magnet Grade | N42 (Br ≥ 14.8 KGs, Hcj ≥ 10.5 KOe) — Customization |

Dimension | L18xW10xT5 (R2) |

Tolerance | ±0.05 mm (Length, Width, Thickness)

|

Operating Temperature | ≤ 80°C (Customizable high-temp versions available)

|

Density | ≥7.5 g/cm³

|

Surface Magnetic Field

| 2100 Gauss (Measured using Japan TM-801 Gauss meter) |

Magnetic Flux | 1.8 mWb (Measured; value varies by material grade) |

3.Manufacturing Process:

To enhance this strong magnetic force energy efficient stable compact segmented radial arc ndfeb magnet ‘s corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

Edge Reinforcement: Laser cladding with nickel-based alloy at magnet seams (prevents electrochemical corrosion)

Edge Rounding: Reduces magnetic field distortion

Default Coating: Triple layer Ni-Cu-Ni (customizable)

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm)

Optional Coatings: Gold or silver plating for better conductivity and corrosion resistance

Coating Benefits:

Salt spray resistance and improved oxidation durability

Higher surface hardness and scratch resistance

Enhanced gloss, suitable for exposed parts

Automatic Optical Inspection (AOI):

AOI stands for Automatic Optical Inspection — a vision-based technology used to inspect products for defects, dimensional inaccuracies, and surface flaws using high-resolution cameras and intelligent software.

4. Packaging and Shipping:

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

We understand logistics is more than just transport — it's about your commitment and customer satisfaction. Our solutions offer:

Global logistics support.

End-to-end visual tracking.

Multiple layers of transport safety.

One-on-one customer service for tailored shipping plans.

With our reliable land, sea, and air logistics network, we empower your business to go further and soar higher.

Q: How to choose the correct magnetization direction?

Axial Magnetization: Magnetic lines flow through thickness — best for concentrated fields.

Radial Magnetization: Magnetic lines radiate outward — for uniform field distribution.

Multipole Magnetization: Multiple poles along circumference — for complex fields (e.g., motors, sensors).

Q: What is the maximum working temperature of a Segmented radial magnet?

Standard N-series: up to 80°C.

High-temp grades (SH/UH/EH): up to 150°C–230°C.

Dysprosium-enriched formulations can further enhance temperature resistance.

Q: Does magnetism decay over time?

Under normal conditions (room temp, dry, no heavy vibration), NdFeB magnets exhibit excellent time stability (<5% loss over 10 years). However, factors like:

Temperature overrun.

Strong external magnetic fields.

Surface corrosion.

Mechanical impact may affect performance.

For samples, technical datasheets, MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001, and other certificates, please contact our sales engineers.

Customization & Service:

Custom magnet size, shape, and coating (layers, thickness, color).

Tailored magnetization direction and field strength.

Laser engraving service for logos or serial numbers.

Packaging and suction force testing for special applications.

Contact Us

Phone/WhatsApp/WeChat: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat