The heat resistance high torque single stable Nickel-plating compact countersunk block magnets are high-performance permanent magnets featuring a Countersunk hole design for secure mechanical fastening.

High torque Single Nickel-plating compact countersunk block magnets

1. Product Overview

The heat resistance high torque single stable Nickel-plating compact countersunk block magnets are high-performance permanent magnets featuring a Countersunk hole design for secure mechanical fastening. It is manufactured using high-grade NdFeB material (e.g., N35–N52) and coated with triple-layer nickel plating (Ni-Cu-Ni), significantly improving corrosion resistance and surface durability. It is ideal for applications requiring both strong magnetic performance and robust mechanical mounting.

2. Technical Parameters

- Product Name: High torque Single Nickel-plating compact countersunk block magnets

- Magnet Grade: N38 (Br ≥ 13.2 KGs, Hcj ≥ 10.8 KOe)

- Dimensions: L10x3x6

- Dimensional Tolerances: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

- Working Temperature: ≤ 80°C (custom high-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 2500 Gauss (measured with TM-801 Gauss meter, Japan)

- Magnetic Flux: 2mWb (measured with fluxmeter)

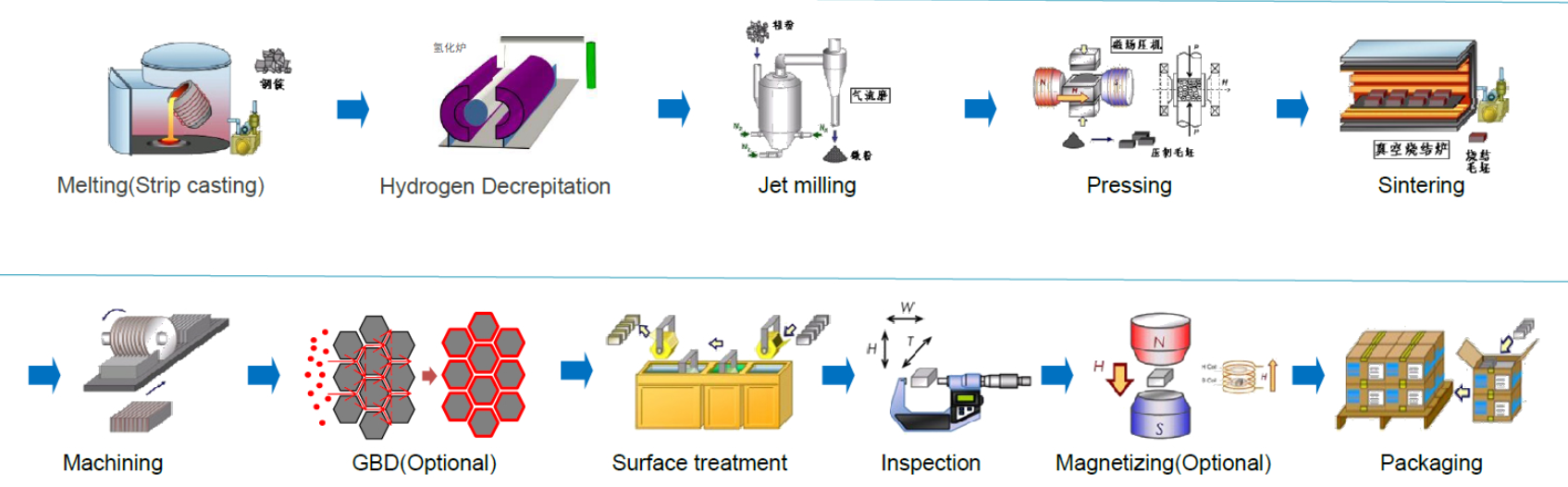

3. Manufacturing Process

Countersunk Hole Drilling:

High-precision CNC or automated drilling ensures consistent hole diameter, depth, and countersink angle.

Magnetization Process:

Professional pulse magnetization equipment is used to inject strong and stable magnetic fields, ensuring the magnet meets design specifications and performs reliably under high load or high-frequency operation.

Grinding & Fine Finishing:

Advanced precision equipment grinds the magnet surface to ensure smoothness and tight dimensional tolerances, supporting high-precision industrial applications.

4. Surface Treatment & Plating Technologies

Ni Coating:

Offers enhanced chemical resistance and waterproofing, especially suitable for humid environments.

Triple Nickel Plating:

Ni-Cu-Ni electroplating dramatically enhances corrosion resistance and mechanical durability.

5. Appearance & Dimensional Inspection Standards

Manual Inspection with Micrometer/Caliper:

Ensures dimensional accuracy per design specification.

Visual Inspection:

Performed under standard lighting to detect cracks, surface defects, or imperfections.

2D Optical Measurement System:

Used for irregular or complex-shaped parts to verify geometric and dimensional accuracy

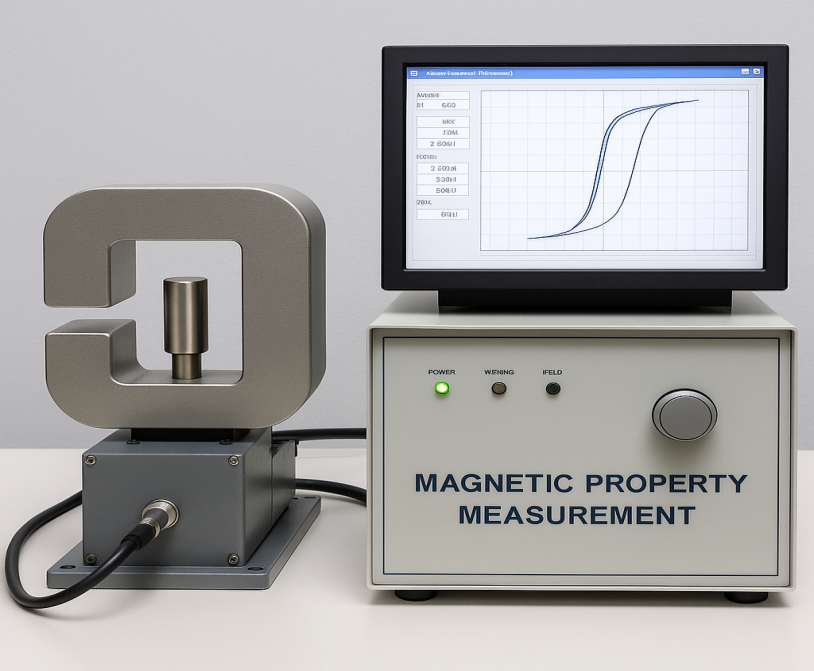

Magnetic Flux Testing:

Ensures consistent magnetic strength across each production batch.

6. Packaging & Transportation

Defect Sorting:

Visual and dimensional defects are removed before final packing

Magnetizing & Arranging:

Each magnet is uniformly magnetized and packed as per customer requirements.

Vacuum Packaging:

Prevents moisture and magnetic interference during shipping and storage.

Outer Packaging:

Shock-resistant, moisture-proof, and anti-magnetic interference packaging ensures safe transportation.

7. Application Fields

Industrial Automation:

Fixtures, jigs, robotic arms — Square-sunk holes allow secure screw mounting for accurate positioning.

Tools & Equipment:

Positioning of electric tool components; removable magnetic covers for instruments.

Sensors & Detection Devices:

Magnetic sensors, reed switches, and position detectors.

Medical & Electronic Devices:

Mounting of portable medical devices and electronic modules — strong, stable force without interfering with sensitive electronics.

Usage Precautions

Handling:

NdFeB magnets are hard yet brittle—avoid dropping, collision, or edge impact.

Safe Operation:

Strong magnetic force may cause pinching—slide magnets apart instead of forcing them.

Proper Installation:

Identify and align polarities correctly to ensure stable operation.

Storage Conditions:

Avoid high temperatures, humidity, and corrosive (acid/alkali) environments.

Magnetic Interference:

Keep magnets away from sensitive equipment like hard drives, IC cards, and pacemakers.

10. Customization & Services

Customized dimensions, shapes, coating layers/thickness/color

Magnetic polarity and force specification

Laser engraving for logos or serial numbers

Encapsulation solutions and pull-force testing for specialized applications

If you require samples, technical datasheets, or certifications such as MSDS, RoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, or ISO 27001, our sales engineers are ready to assist you.

Contact Us:

Phone/ WeChat/ WhatsApp : +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat