Precision customized high torque stable compact permanent Single-Countersunk NdFeB Mounting-shaped Magnets , these magnets feature a Ni coating formed through precision wire cutting and oriented magnetization.

Permanent Single-Countersunk NdFeB Mounting-shaped Magnets

2025-7-17

1. Product Overview

Precision customized high torque stable compact permanent Single-Countersunk NdFeB Mounting-shaped Magnets , these magnets feature a Ni coating formed through precision wire cutting and oriented magnetization. The unique sector design enables efficient magnetic flux concentration, while the coating provides superior insulation and corrosion resistance. Ideal for space-constrained applications requiring precise magnetic field control, such as magnetic encoders, and medical imaging equipment.

2. Technical Parameters

Product Name | Permanent Single-Countersunk NdFeB Mounting-shaped Magnets |

Grade | N42 (Br ≥13.8 kGs, Hcj ≥12.4 kOe) |

Dimension | D20x8x4mm (C-3) |

Tolerance | L±0.05mm, W±0.05mm, T±0.05mm |

Operating Temperature | ≤80°C (High-temp version customizable) |

Density | ≥7.5 g/cm³ |

Surface Field | 2100Gauss (Measured with TM-801 Gauss meter) |

Magnetic Flux | 2.2 mWb (Fluxmeter tested) |

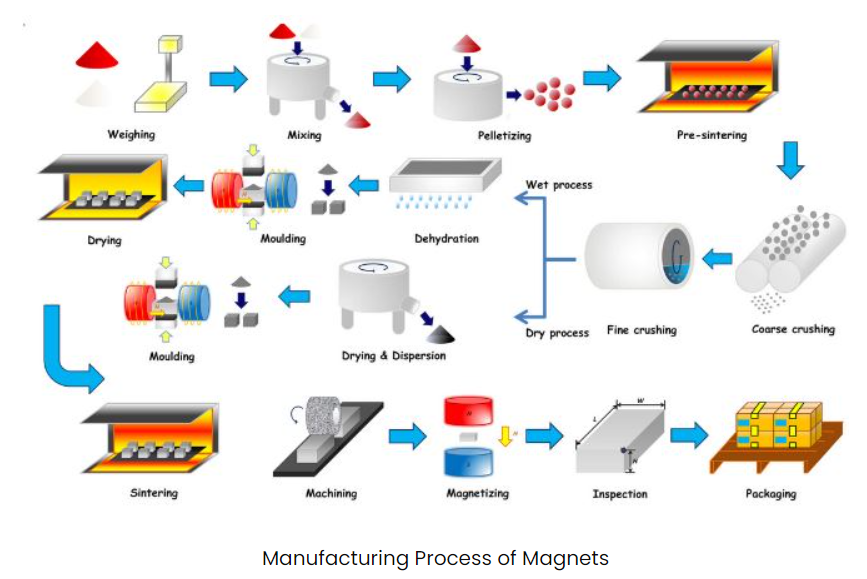

3. Manufacturing Process

The Key production stages of this industrial use high remanence Permanent Single-Countersunk NdFeB Mounting-shaped Magnets are as following:

- Edge Reinforcement:

- Laser cladding with NiCrBSi alloy on edges enhances impact resistance.

- Curved Surface Adhesion Optimization:

- Plasma activation technology improves coating bonding strength.

- Multi-stage Magnetization:

- Radial magnetization with laser positioning marks reduces field uniformity error.

- Oriented magnetization via multi-pole magnetizing heads with sequential pulsing.

4.Surface Treatment & Plating

- Edge Reinforcement: Laser-clad nickel alloy at seams (prevents electrochemical corrosion).

- Edge Rounding: Minimizes magnetic field distortion.

- Standard Plating: Triple-layer Ni-Cu-Ni (customizable upon request).

- Plating Thickness: Ni(3μm) + Cu(5μm) + Ni(4μm) (adjustable).

- Electrophoretic Coating: Uniform corrosion-resistant decorative finish applied via electrodeposition.

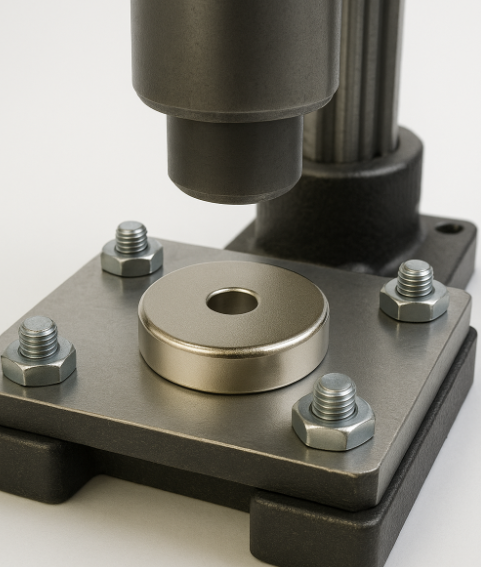

5. Appearance & Dimensional Inspection

Quality control procedures:

- Manual measurement (micrometer/caliper)

- Visual inspection (800-1200 lux at 20-750px distance)

- Optical comparator for complex geometries

- CCD automated sorting for full appearance/dimension check

- Magnetic flux consistency verification

6. Reliability Testing

6.1 Environmental Adaptability

- Temperature cycling: -40°C to +80°C

- Humidity test: >90% RH exposure

- Salt spray test: ASTM B117 standard

6.2 Aging Tests

- Natural aging (months/years)

- Accelerated aging (thermal/humidity/magnetic stress)

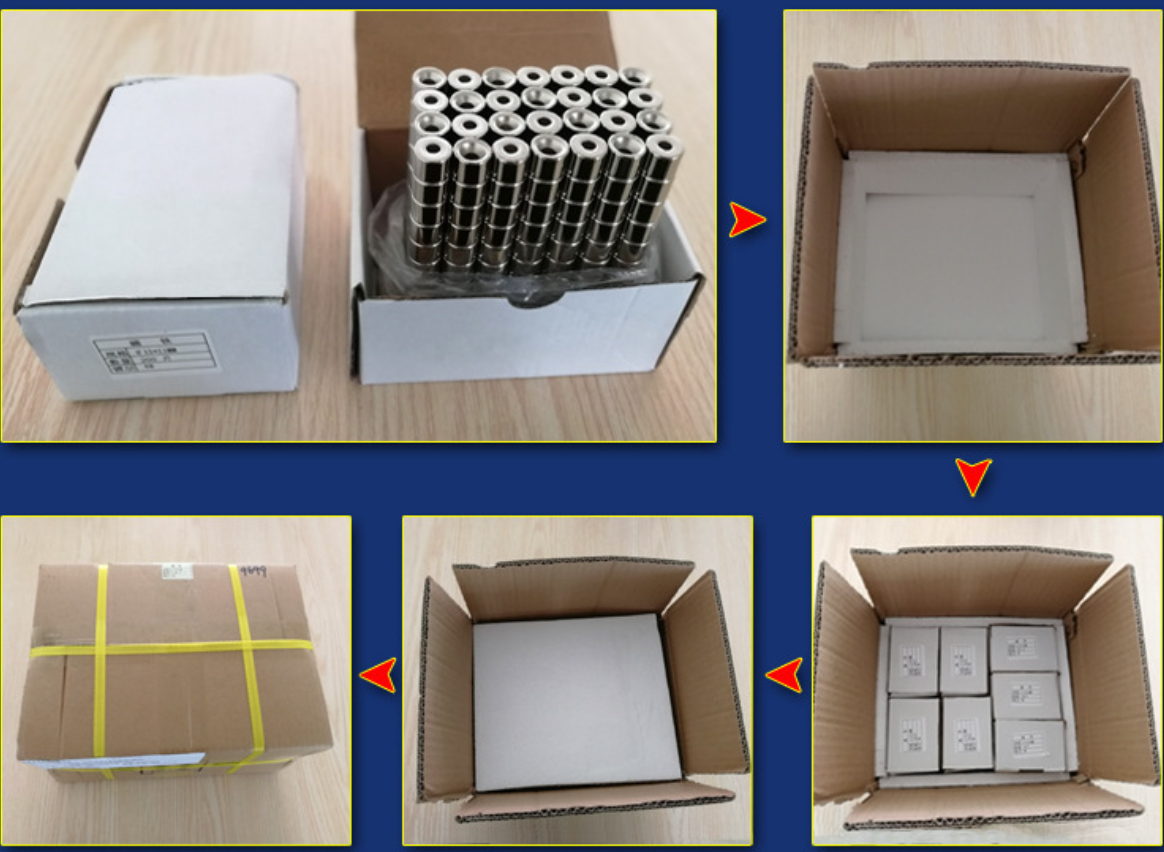

7. Packaging Process

- Defective unit removal

- Uniform magnetization and alignment

- Customized boxing/labeling

- Vacuum sealing with magnetic shielding & cushioning

- Moisture/impact/magnetic interference-proof master cartons

8. Shipping Options

Air Freight

Fastest method; ideal for urgent or high-value orders.

Shielding required to comply with IATA PI902 standards:

Magnetic field strength must not exceed 0.159 A/m (200 nT) at 4.6 m (15 ft) from the package

Typically done with iron/steel sheets or custom shielding enclosures.

Sea Freight

Ideal for large quantities or heavy items (e.g., >100 kg).

More cost-effective, but slower.

No magnetic shielding requirement for ship cargo, but moisture control (e.g., VCI bags, desiccant) is essential.

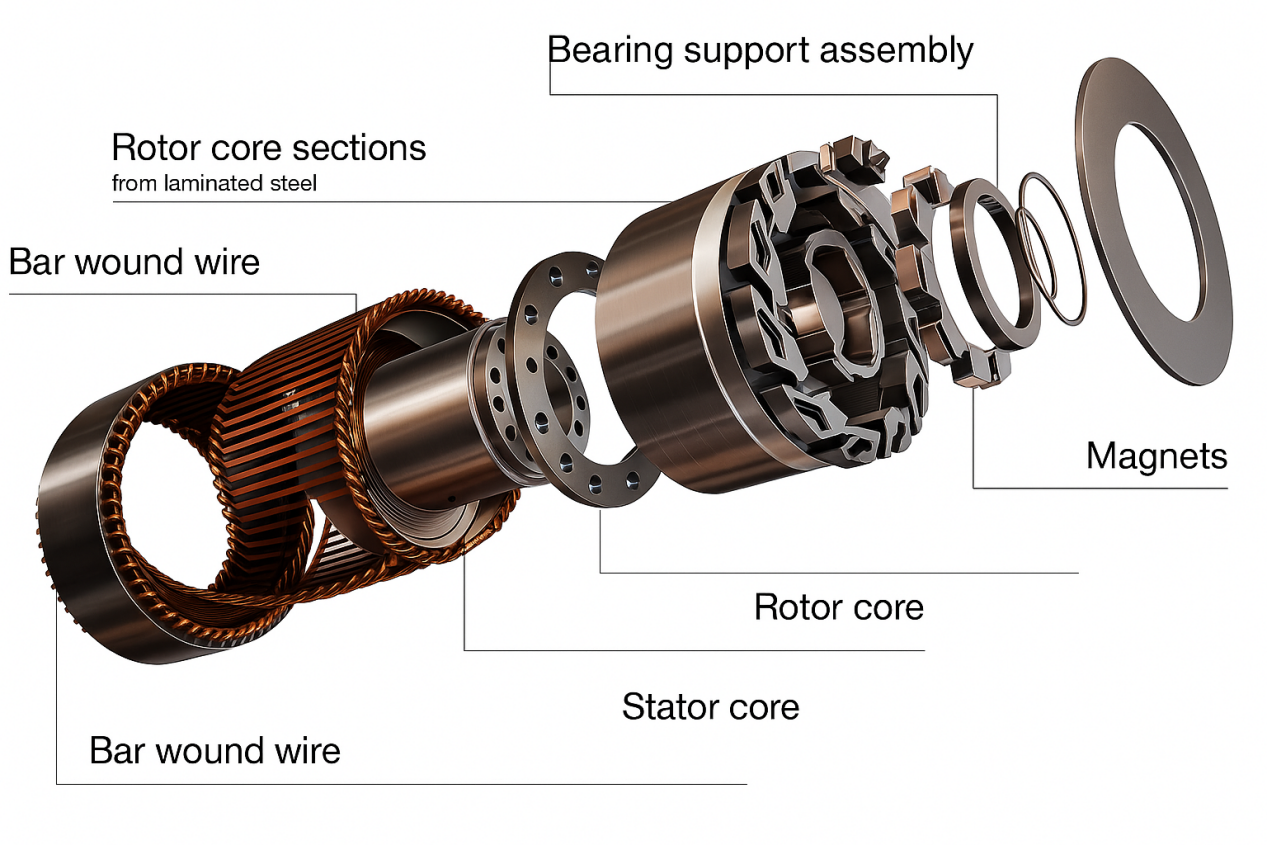

9. Application Fields

Magnetic Sensors: Custom shapes can enhance the sensitivity and accuracy of magnetic sensors used in compasses, navigation systems, and scientific instruments.

Electric Motors and Generators: Polygonal magnets can improve the efficiency and performance of electric motors and generators by optimizing magnetic field distribution within the machine.

Magnetic Couplings: These magnets can be used in magnetic couplings to transmit torque between two rotating shafts without direct physical contact, thus eliminating the need for mechanical seals.

Magnetic Bearings: Polygonal magnets can be utilized in magnetic bearings, which support rotating shafts or components without the need for traditional mechanical bearings, reducing friction and wear.

10. Usage Precautions

- Handle with care: Avoid impacts/drops (NdFeB is brittle).

- Pinch hazard: Use sliding motion during handling.

- Polarity identification: Correct orientation prevents operational faults.

- Environmental protection: Store away from moisture/corrosives.

- EMI prevention: Keep away from pacemakers, credit cards, and electronics.

- Safety: Child-safety for small magnets; impact protection for industrial sizes.

- Corrosion management: Select coated versions for harsh environments.

11. Customization & Services

Supported options:

- Dimensions/shape/plating (layers, thickness, color)

- Polarity direction/magnetic strength

- Laser marking (logos/SNs)

- Application-specific packaging & pull force testing

Contact Us:

Phone: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

.jpg)

Jinconn WeChat