Custom industrial use premium quality high torque heat resistant stable Motor Spindle-shaped Magnets , these magnets feature a Ni coating formed through precision wire cutting and oriented magnetization.

Custom premium quality heat resistant Motor Spindle-shaped Magnets

2025-7-17

1. Product Overview

Custom industrial use premium quality high torque heat resistant stable Motor Spindle-shaped Magnets , these magnets feature a Ni coating formed through precision wire cutting and oriented magnetization. The unique sector design enables efficient magnetic flux concentration, while the coating provides superior insulation and corrosion resistance. Ideal for space-constrained applications requiring precise magnetic field control, such as magnetic encoders, and medical imaging equipment.

2. Technical Parameters

Product Name | custom premium quality heat resistant Motor Spindle-shaped Magnets |

Grade | N48 (Br ≥13.8 kGs, Hcj ≥12.4 kOe) |

Dimension | D20x8x4mm (R-1.5) |

Tolerance | L±0.05mm, W±0.05mm, T±0.05mm |

Operating Temperature | ≤80°C (High-temp version customizable) |

Density | ≥7.5 g/cm³ |

Surface Field | 2100Gauss (Measured with TM-801 Gauss meter) |

Magnetic Flux | 2.2 mWb (Fluxmeter tested) |

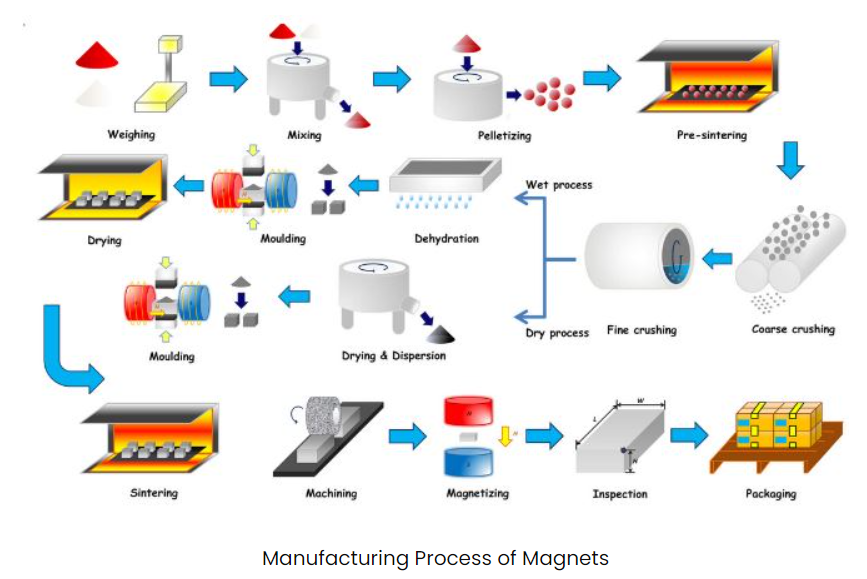

3. Manufacturing Process

The Key production stages of this customized premium quality heat resistant flexible magnetic tile energy efficient Motor Spindle-shaped Magnets are as following:

- Edge Reinforcement:

- Laser cladding with NiCrBSi alloy on edges enhances impact resistance.

- Curved Surface Adhesion Optimization:

- Plasma activation technology improves coating bonding strength.

- Multi-stage Magnetization:

- Radial magnetization with laser positioning marks reduces field uniformity error.

- Oriented magnetization via multi-pole magnetizing heads with sequential pulsing.

4. Surface Treatment & Coating Technology

- Copper Undercoating: Enhances adhesion and fills micro-porosity.

- Ni-Cu-Ni Coating: A three-layer plating that improves rust, corrosion, and abrasion resistance.

- Epoxy Coating: Black or gray finish; enhances thermal resistance and is suitable for humid or chemical environments.

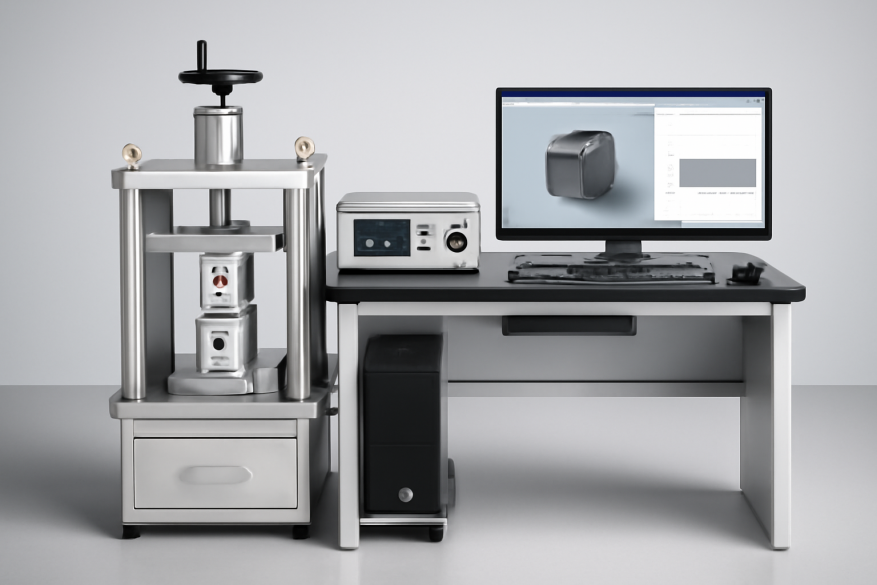

5. Appearance & Dimensional Inspection Standards

- Manual measurement using micrometer/caliper

- Visual inspection under 800–1200 lumens

- 2D optical inspection for non-standard shapes

- CCD auto-sorting and full appearance/dimensional check

- Magnetic flux testing to ensure magnetic consistency

6. Reliability Testing

-Thermal Shock Cycling Test:

Evaluates the structural integrity and coating adhesion of magnets under extreme temperature fluctuations.

- Magnetic Performance Consistency Test:

Uses a Gaussmeter to verify the uniformity of surface magnetic field, remanence, and magnetic flux across different production batches, ensuring minimal performance deviation that could affect final assembly or operational stability.

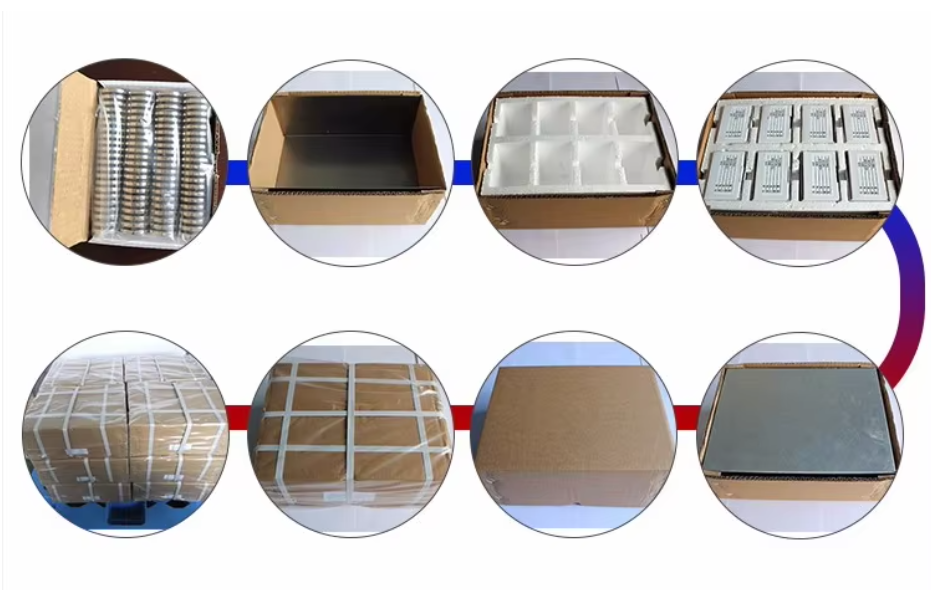

7. Packaging Process

Items with cosmetic or dimensional defects are eliminated through strict inspection

Qualified units are magnetized in batches and arranged in order

Packed per client specifications with customized labeling

Each unit is vacuum-packed with magnetic shielding and shockproof padding for enhanced protection

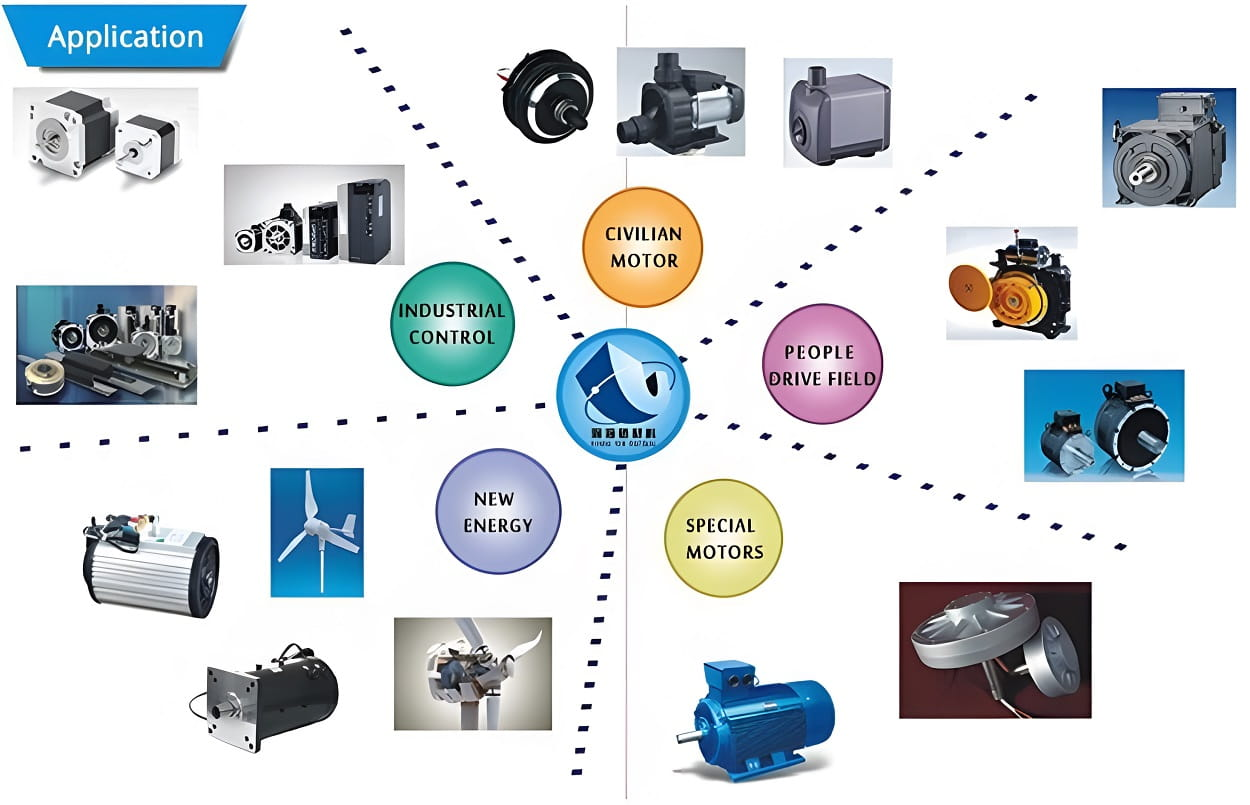

8. Application Fields

- Motor Systems: Brushless, stepper, and servo motors, Bluetooth earphone, headphone

- Sensor Components: Hall sensors, encoders, displacement detectors

- Medical Devices: MRI systems, electromagnetic clamps

- Consumer Electronics: Magnetic connectors, wireless charging rings

- Industrial Automation: Magnetic coupling systems, transmission parts

- New Energy: EV drives, wind power generators, sensor motor magnet

9. Usage Precautions

- Avoid impact or dropping; NdFeB is brittle

- Use sliding motion to separate to avoid pinching

- Install with correct polarity to ensure device stability

- Store away from heat, humidity, and corrosive environments

- Keep away from sensitive electronics (pacemakers, hard drives, IC cards)

10. Customization & Services

- Customizable parameters: dimensions, shape, magnetization direction, coating thickness

- Optional laser marking for logos or serial numbers

- Support for sample testing, pull-force testing, and packaging solutions, industrial motor magnet.

We are delighted to provide complimentary customized magnet solutions designed to meet your unique requirements.

Contact Us:

Phone: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

.jpg)

Jinconn WeChat