Precision customized high adhesive force high torque powerful permanent ndFeB compact round Ring Magnets are rare earth permanent magnetic materials composed primarily of Neodymium (Nd), Iron (Fe), and Boron (B), manufactured via high-precision sintering processes.

High torque powerful permanent ndFeB compact round Ring Magnets

1. Product Overview

Precision customized high adhesive force high torque powerful permanent ndFeB compact round Ring Magnets are rare earth permanent magnetic materials composed primarily of Neodymium (Nd), Iron (Fe), and Boron (B), manufactured via high-precision sintering processes. These High torque powerful energy efficient permanent lightweight ndFeB compact round Ring Magnets exhibit excellent magnetic properties, high energy product (BHmax), and structural diversity. They are widely used in motors, sensors, speakers, medical devices, automation equipment, and renewable energy systems. The ring-shaped structure allows for easy assembly, controlled magnetic flux direction, and improved magnetic circuit efficiency—ideal for hollow mounting or axial magnetic field design applications.

2. Technical Specifications

Product Name | High torque powerful permanent ndFeB compact round Ring Magnets |

Magnet Grade | N40 (Br ≥ 13.2 KGs, Hcj ≥ 10.8 KOe) |

Product Dimension | D24-D12*2 |

Tolerance | Outer Diameter ±0.05mm, Thickness ±0.05mm |

Working Temperature | ≤80 (customizable for high-temperature versions) |

Density | ≥ 7.5g/cm³ |

Magnetic Field Strength | 2900 GS |

Magnetic Flux | 2.9 mWb (measured with fluxmeter) |

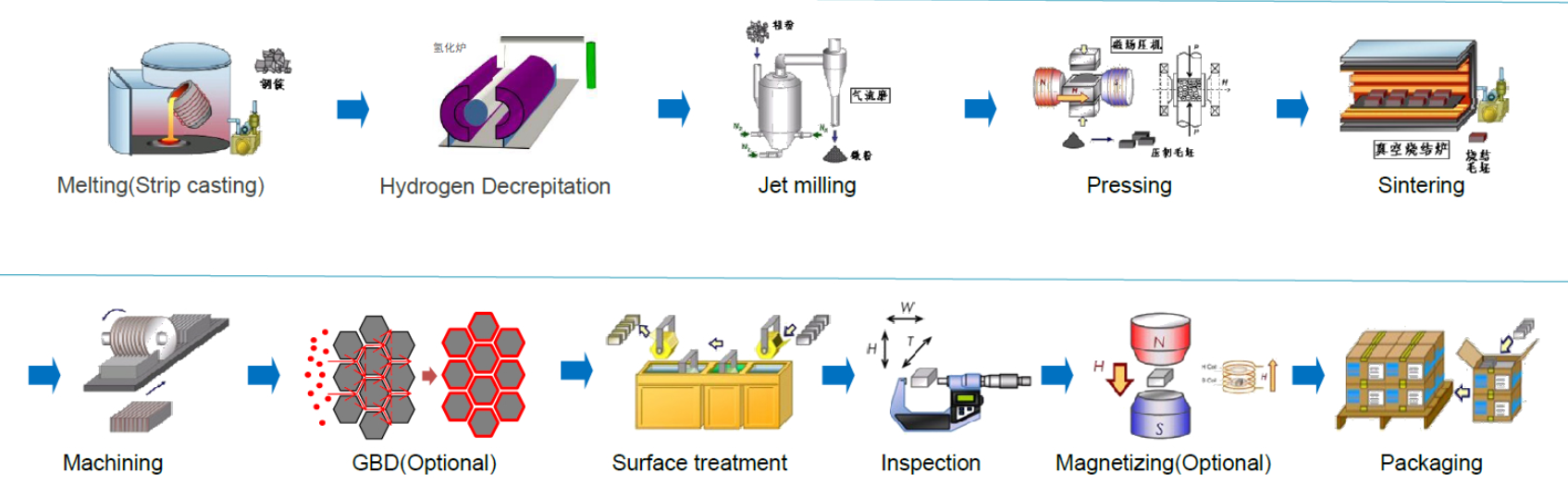

3. Manufacturing Process

• Thin-wall Anti-crack Technology: Ultrasonic-assisted cutting to reduce cutting stress; cryogenic processing to prevent material cracking.

• Wire EDM: Molybdenum wire cuts step profiles with precision of ±0.03mm (requires segmented programming).

• Grain Boundary Diffusion Technology: Surface coating with dysprosium compounds to improve coercivity.

4. Surface Treatment and Coating Technology

To improve this high speed performance high torque strong permanent ndFeB compact round Ring Magnets corrosion resistance and surface quality, the following surface treatments are used:

• Default Coating: Ni-Cu-Ni triple-layer coating (customizable)

• Coating Thickness Standard: Ni (3μm) + Cu (5μm) + Ni (4μm) — customizable upon request

• Optional Coatings: Gold or silver coatings offer excellent conductivity and corrosion resistance

• Degreasing: Organic solvent or alkaline solution cleaning to remove surface oil for optimal adhesion in subsequent treatments

5. Appearance and Dimensional Inspection Standards

To ensure product quality consistency and reliability, all products undergo the following strict inspections:

• Manual Measurement with Micrometer/Caliper

• Visual Inspection under 800–1200 lumen lighting, 20–750px distance

• 2D Optical Measuring System for complex or non-standard structures

• CCD Smart Sorting System for automated full inspection

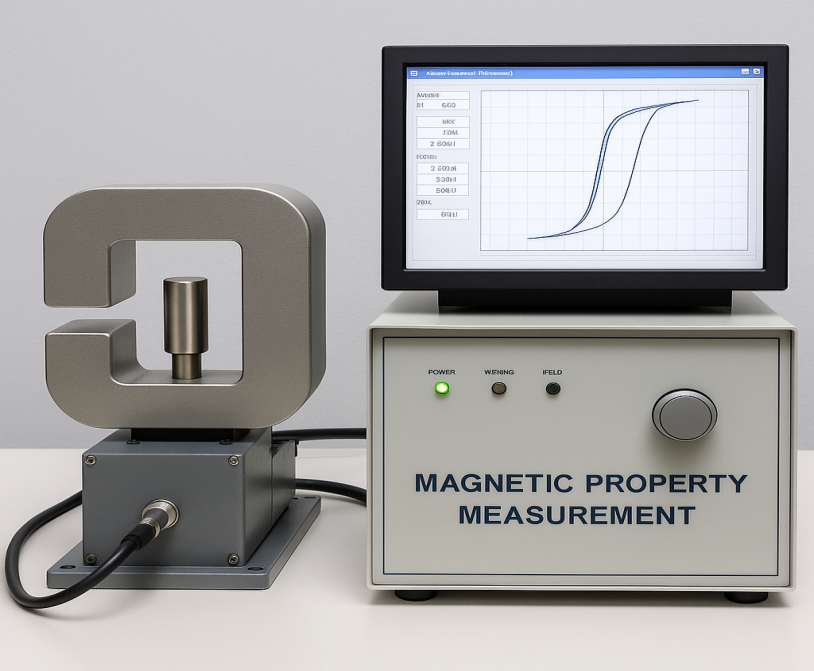

• Magnetic Flux Testing to ensure consistency in magnetic performance across batches

6. Reliability Testing

• Salt Spray Test: Evaluates corrosion resistance of coating in salt mist environment

• Thermal Shock Cycle Test: Assesses structural integrity and coating adhesion under drastic temperature changes

• Magnetic Performance Consistency Test: Ensures surface gauss, remanence, and flux uniformity using gaussmeters and fluxmeters

• Tensile/Bonding Strength Test: Measures adhesive strength for glued or bonded applications to prevent detachment from vibration or aging

7. Packaging Process and Description

In accordance with magnetic product transport requirements, we adopt professional packaging methods:

• Eliminate non-conforming items (appearance or dimensional defects)

• Magnetize and neatly arrange qualified products

• Box and label per customer requirement

• Vacuum packaging with anti-magnetic shielding and cushioning pads

• Inner boxes placed in outer cartons — moisture-proof, shock-proof, and anti-magnetic interference

• Custom packaging available

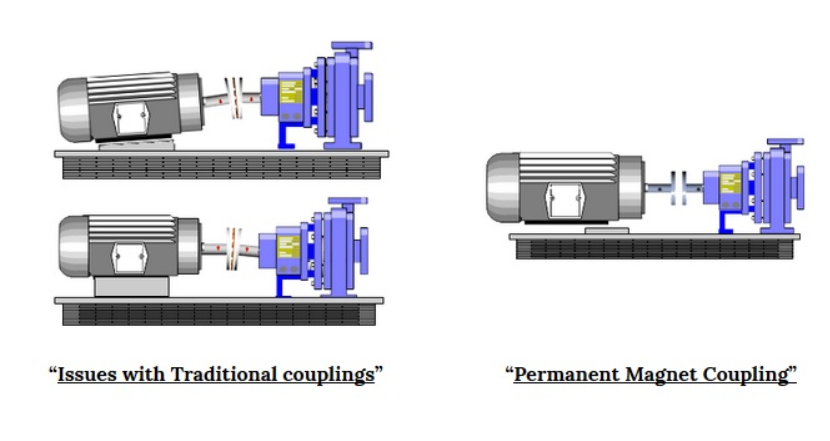

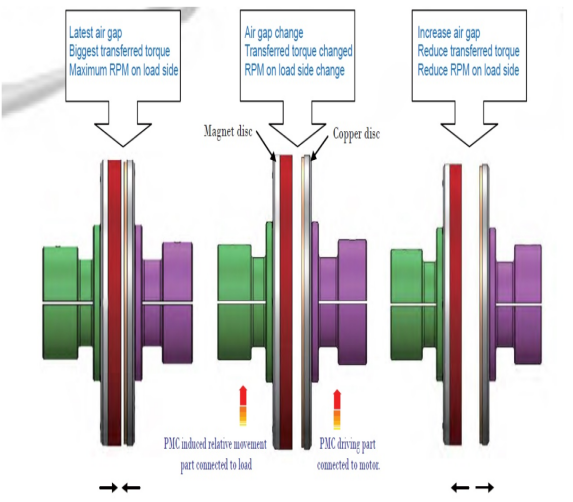

8. Application Fields

Widely applied in:

• Motors & Generators: BLDC motors, wind turbines, stepper motors

• Electronics & Sensors: Magnetic sensors, speakers, earphones

• Medical & Research Devices: MRI machines

• Emerging Fields: Wireless charging, magnetic levitation systems

9. Usage Precautions

• Temperature Limits: Avoid exceeding Curie temperature (310–340°C) to prevent irreversible demagnetization

• Brittleness: Avoid impact or interference fits

• Polarity Identification: Install based on correct pole orientation to ensure proper device operation

• Moisture and Corrosion Protection: Store away from high temperature, humidity, acids, and alkalis

• Keep Away from Sensitive Devices: Maintain safe distance from hard drives, IC cards, pacemakers, etc.

10. Customization and Services

We support a wide range of customization services:

• Dimensions, shape, coating (layers, thickness, color)

• Pole orientation and magnetic strength

• Laser logo engraving or serial number marking

• Encapsulation solutions and suction force testing for special applications

We are pleased to offer free customized magnet solutions tailored to your specific needs.

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

Contact Us:

Phone: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat