This precision- engineered heat resistant powerful high adhesive force Black Epoxy Coated Neodymium compact arc segment magnet with N52 grade, featuring extremely high magnetic strength, excellent demagnetization resistance, and precise dimensional accuracy. The product's precision can be customized according to customer requirements.

Precision-engineered super strong high adhesive force Black Epoxy Coated Neodymium compact arc segment magnet

1. Product Overview

This precision- engineered heat resistant powerful high adhesive force Black Epoxy Coated Neodymium compact arc segment magnet with N52 grade, featuring extremely high magnetic strength, excellent demagnetization resistance, and precise dimensional accuracy. The product's precision can be customized according to customer requirements. Its sophisticated ring-shaped design meets high-performance magnetic needs in compact spaces, making it widely applicable in high-end electronic devices, audio equipment, premium perfume bottle caps, and other fields.

The precision- engineered super strong high adhesive force stable Black Epoxy Coated Neodymium small arc segment magnet is manufactured using advanced wire cutting, center-less grinding, and double-disc grinding processes, ensuring neat edges and uniform dimensions. Surface treatment includes multi-layer metal coating (Ni+Cu+Ni) or optional Zn coating, effectively preventing oxidation and corrosion from environmental factors, thereby extending the product's service life.

These NdFeB arc magnets exceeded our expectations in high-speed motor applications. The strong magnetic force and precision arc shape made assembly seamless, and the epoxy coating provided excellent durability against corrosion. Ideal for our brushless motor production line

2. Technical Specifications:

Product Name | Precision- engineered super strong high adhesive force Black Epoxy Coated Neodymium compact arc segment magnet |

Material Grade | N52 (Br ≥ 14.2 kGs, Hcj ≥ 12 kOe) |

Dimension | D20-D14×6 mm (R3) |

Dimensional Tolerance | ±0.05 mm (length/width/thickness) |

Operating Temperature | ≤80℃ (high-temperature versions customizable) |

Density | ≥7.5 g/cm³ |

Surface Magnetic Field | 3200 ± 200 Gauss (measured with Japanese TM-801 Gauss meter)

|

Magnetic Flux Value | 2.3 mWb (measured with fluxmeter) |

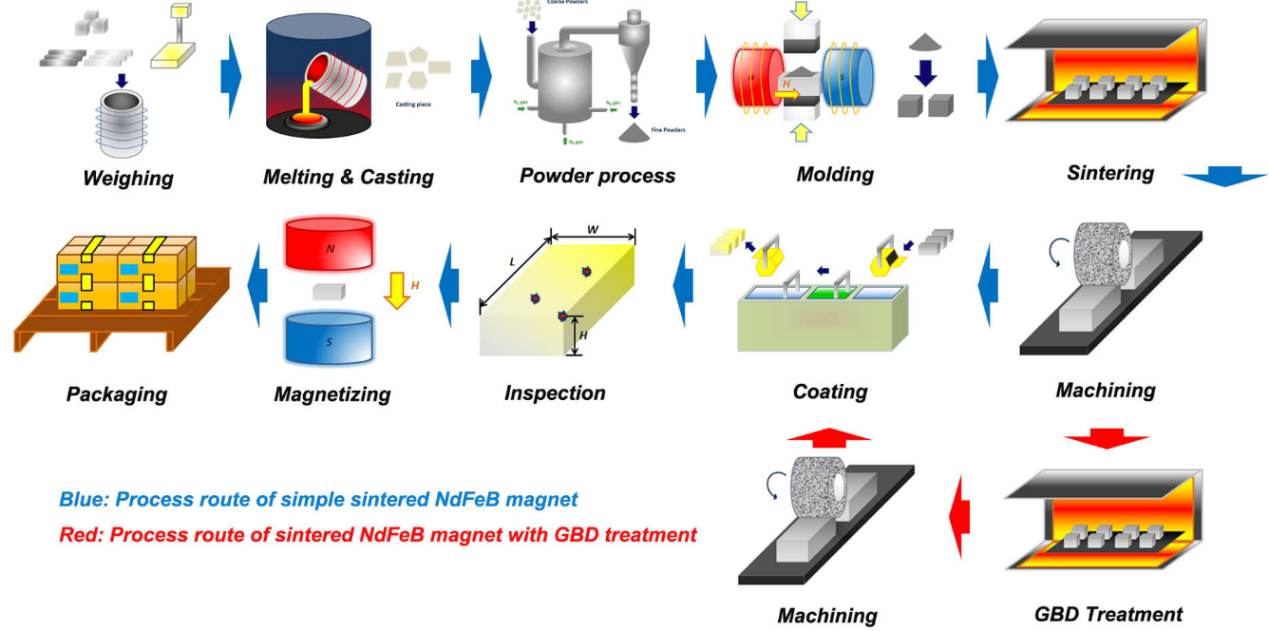

3. Manufacturing Process

The customized precision- engineered super strong energy efficient high adhesive force Black Epoxy Coated Neodymium compact arc segment magnet is manufactured through the following key processes:

l Wire Cutting: Uses molybdenum/copper wire cutting equipment to achieve ±0.02mm precision for small-batch custom rings.

l Centerless Grinding: Refines inner and outer diameters to ensure roundness (±0.05mm tolerance).

l Double-Disc Grinding: Controls thickness and parallelism.

4. Surface Treatment and Coating Technology

To enhance corrosion resistance and appearance quality, the following surface treatment solutions are adopted:

l Default Coating: Triple-layer nickel-copper-nickel (Ni-Cu-Ni). Coating can be customized according to customer requirements.

l Coating Thickness Standard: Ni (3μm) + Cu (5μm) + Ni (4μm). Coating thickness can be customized as needed.

l Optional Coating: Single-layer zinc (Zn 5μm) for cost-sensitive projects.

Coating Features:

l Resistant to salt spray corrosion and improved oxidation resistance.

l Increased surface hardness to prevent scratches.

l Enhanced appearance glossiness, suitable for exposed components.

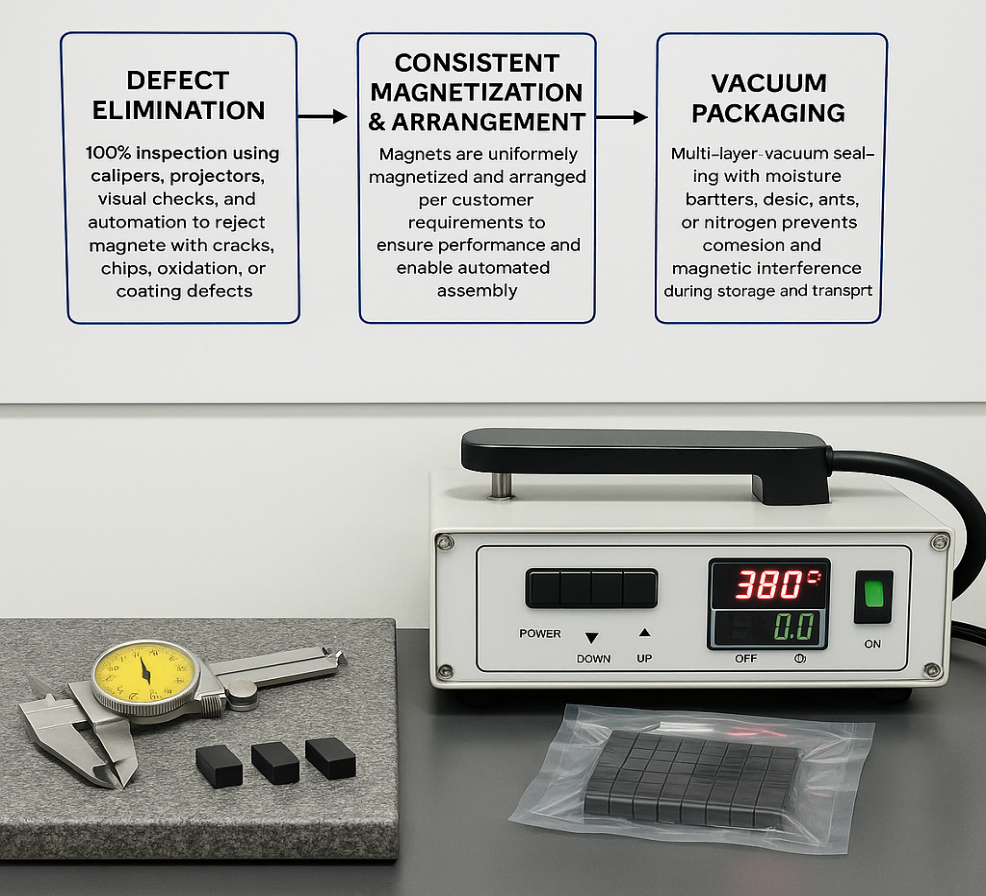

5. Appearance and Dimensional Inspection Standards

To ensure consistent and reliable product quality, all products undergo the following inspection processes:

Manual dimensional inspection with micrometers/calipers.

Visual inspection (under 800-1200 lumen lighting at 20-30 cm standard inspection distance).

2D image measurement for precise dimensional verification.

Automated CCD sorting and full inspection of product appearance and dimensions.

Magnetic flux testing to ensure batch consistency of magnetic performance.

6. Reliability Testing:

l Neutral Salt Spray Test (NSS):

Temperature: 35℃ ±2℃

Salt spray deposition rate: 1~2 ml / 2000px²·h

pH value: 6.5 ~ 7.2

Test duration: 24h / 48h / 72h / 96h (can be set according to application scenarios/customer requirements).

l Thermal Demagnetization Test:

Placed in a constant-temperature oven (80℃) for 2 hours (test duration can be adjusted per customer requirements).

Demagnetization rate ≤10% is considered qualified.

Simulates thermal stability in real-world applications.

l Drop Test Notice:

This product is not suitable for drop tests as neodymium magnets are brittle and strong impacts may cause chipping or cracking.

7. Packaging Process and Instructions

In compliance with magnetic product transportation requirements, we implement professional packaging methods:

l Defective items in appearance and dimensions are removed.

l Qualified products are uniformly magnetized and neatly arranged.

l Customized box quantities and labels per customer requirements.

l Each box is vacuum-packed with magnetic shielding plates and shock-absorbing pads.

l Small boxes are packed into master cartons with moisture, impact, and magnetic interference protection.

Packaging methods can be customized.

8.Shipping:

8.1 Shipping Challenges with NdFeB Magnets

Due to their strong magnetic field, shipping neodymium magnets—especially in bulk or large sizes—requires special care. Key challenges include:

Magnetic Interference

Strong fields can interfere with aircraft instruments, especially if not properly shielded.

International Air Transport Association (IATA) imposes strict regulations for air freight.

Fragility

NdFeB magnets are brittle and prone to chipping, especially during vibration or collision in transit.

8.2 Shipping Options

Air Freight

Fastest method; ideal for urgent or high-value orders.

Shielding required to comply with IATA PI902 standards:

Magnetic field strength must not exceed 0.159 A/m (200 nT) at 4.6 m (15 ft) from the package

Typically done with iron/steel sheets or custom shielding enclosures.

Sea Freight

Ideal for large quantities or heavy items (e.g., >100 kg).

More cost-effective, but slower.

No magnetic shielding requirement for ship cargo, but moisture control (e.g., VCI bags, desiccant) is essential.

Ground/Express Courier (DHL, UPS, FedEx)

Good for small and medium volumes.

Couriers may require magnetic declaration and limited field strength—shielding still needed for high-grade magnets

8.3 Documents & Labeling Requirements

Required Documentation:

Commercial Invoice

Packing List

Magnetic Field Test Report (especially for air shipments)

Shipper’s Declaration for Dangerous Goods (if applicable)

MSDS (Material Safety Data Sheet)

Labeling:

Magnetized Material — Handle with Care”

Class 9 Hazard label if magnetization exceeds safe limits (usually for unshielded air shipments)

Orientation arrows (if stacked)

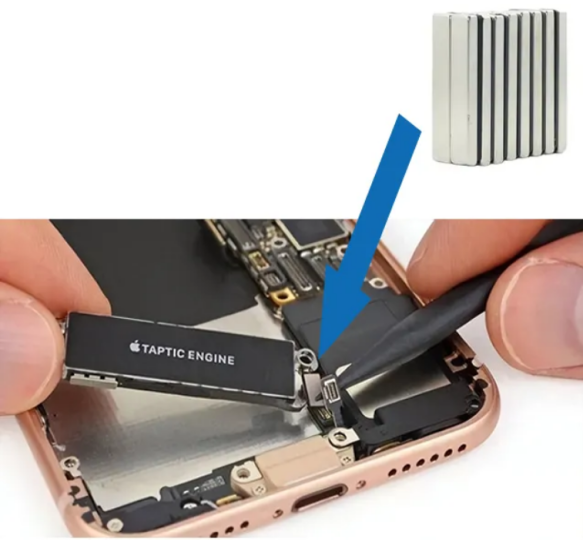

9. Application Fields:

This product is widely used in:

l Smart wearable devices: Magnetic structures for smart bands, earbud positioning, electric toothbrush chargers.

l Audio equipment: Speaker and headphone magnetic circuits (Hi-Fi systems, TWS earbuds).

l Industrial applications: Motor cores, sensors, braking systems in power tools.

10. Usage Precautions:

l Handle with care: Neodymium magnets are brittle—avoid impacts or drops.

l Avoid pinching: Always slide magnets apart instead of pulling directly.

l Store properly: Keep away from high temperatures, humidity, and corrosive environments.

l Safety warning: Keep strong magnets away from electronic devices, credit cards, and medical implants like pacemakers.

11. Customization and Services:

We support various customization services:

l Size, shape, and coating (layer count, thickness, color) customization.

l Polarity direction and magnetic strength adjustment.

l Laser-engraved logos or serial numbers.

l Special application packaging solutions and pull-force testing support.

If you need any solution for your mobile, speaker or robotics project technical data sheet,please feel free to contact our sales engineers, we are always ready to assist you!

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

.

Contact Us

Phone/WhatsApp/WeChat: +86 18038225892

Email: helen@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat