Precision customized industrial-grade high coercivity top-notch strong magnetic resilient roof shaped NdFeb magnet is meticulously engineered to meet the stringent demands of modern compact and irregular-shaped magnetic applications.

Precision customized industrial- grade high quality strong magnetic sturdy roof shaped NdFeb magnet

1. Product Overview & Application Scenarios

Precision customized industrial-grade high coercivity top-notch strong magnetic resilient roof shaped NdFeb magnet is meticulously engineered to meet the stringent demands of modern compact and irregular-shaped magnetic applications. Crafted from premium-grade sintered NdFeB, it provides exceptional magnetic strength while offering outstanding dimensional adaptability for space-constrained or structurally complex assemblies.With a high remanence and strong intrinsic coercivity, the customized industrial grade heat resistance premium magnetic strength roof shaped NdFeb magnet maintains reliable performance even under dynamic or thermally demanding environments.

This tailored professional grade corrosion resistance high quality magnetism roof shaped NdfeB magnet offers precise magnetic control and strong force output in a compact form, making it an ideal solution across multiple industries. In automation, its high magnetic strength ensures stable positioning and gripping for robotic arms. In electronics, its shape and precision tolerance allow seamless integration into compact circuit designs. For medical devices, the magnet’s high stability and corrosion-resistant coatings support reliable performance in sensitive diagnostic or actuation systems. In magnetic coupling systems, its robust magnetic flux enables efficient, non-contact torque transfer in sealed or sterile environments. Together, these advantages support high-performance, miniaturized, and reliable design solutions across all four sectors.

2. Technical Specifications

Product Name: Precision customized industrial- grade high quality strong magnetic sturdy roof shaped NdFeb magnet

Magnet Grade: N45 (Br ≥ 14.8 KGs, Hcj ≥ 10.5 KOe) — Customized

Dimensions: D24-D21×4 mm

Tolerance: ±0.05 mm (Length, Width, Thickness)

Operating Temperature: ≤ 80°C (Customized high-temp versions available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 2400 Gauss (Measured using Japan TM-801 Gauss meter)

Magnetic Flux: 2.2 mWb (Measured; value varies by material grade)

3. Surface Treatment & Coating Technology

To enhance this customized industrial grade fast magnetic response strong magnetic stable roof shaped magnet’s corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

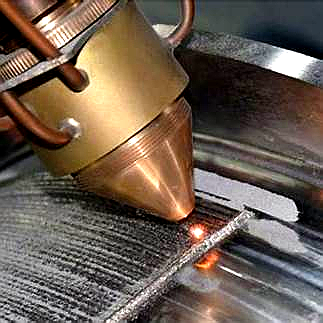

Laser Sealing

High-precision laser treatment further seals surface micro-cracks, effectively enhancing the magnet's salt spray resistance, reaching over 1000 hours.

Nickel Plating (Ni-Cu-Ni Structure)

A three-layer composite coating process is used: copper plating on the inner layer, nickel plating in the middle, and an outer layer of nickel. This structure balances mechanical strength and corrosion resistance, significantly improving the product's protection in harsh environments such as humidity, salt spray, and acidic/alkaline conditions. The nickel layer is dense and hard, effectively preventing rust and chemical corrosion while offering excellent wear resistance. This extends the magnet's lifespan in high-frequency assembly and long-term operation environments. Additionally, the bright silver metallic sheen gives the product a clean, aesthetically pleasing appearance, meeting both functional and aesthetic requirements for industrial and consumer products.

4.Appearance & Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

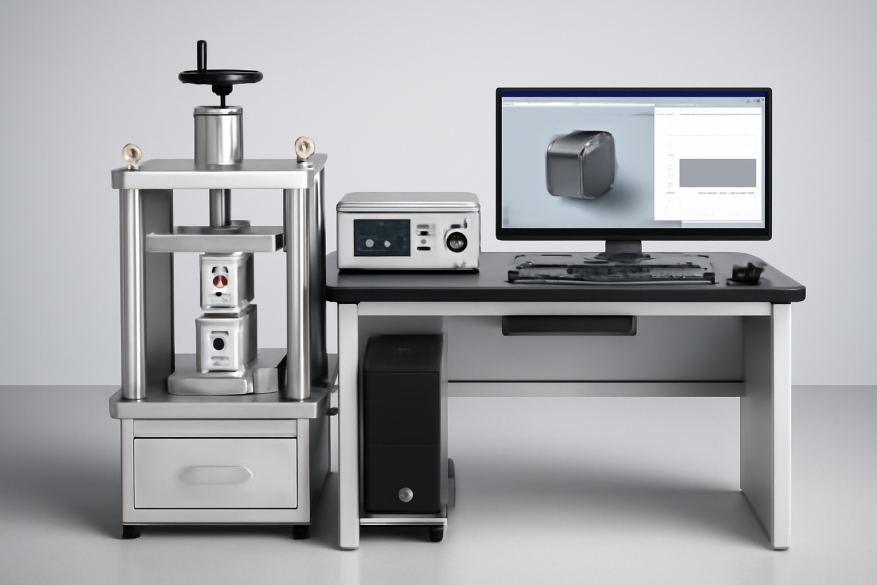

Image Measurement System: High-resolution cameras combined with intelligent algorithms enable contactless two-dimensional measurement, particularly suited for assessing intricate or non-standard shapes. This approach ensures high efficiency and consistent objectivity in large-scale manufacturing.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

5. Reliability Testing

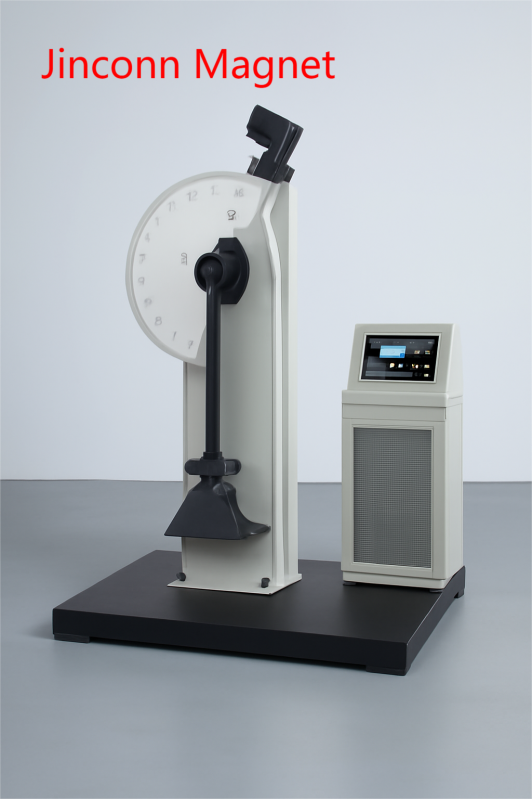

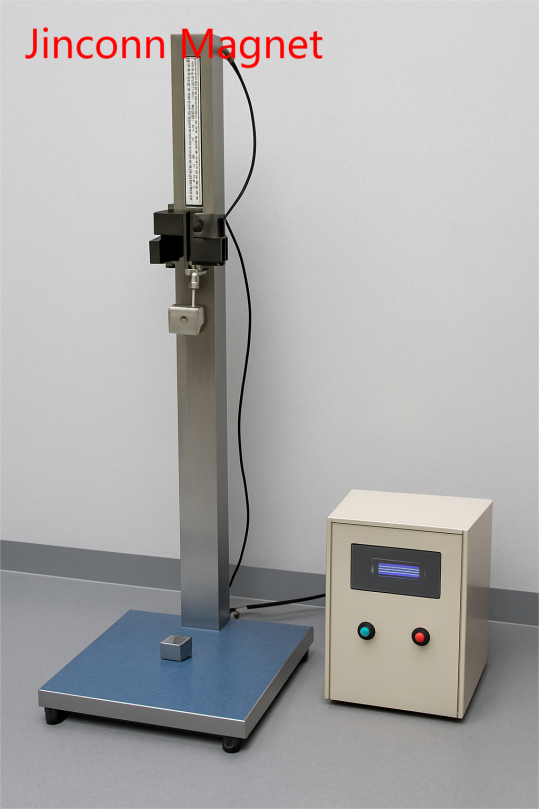

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

6.Packaging & Transportation

Quality Control: Every magnet undergoes 100% inspection using calipers, projectors, and automated systems to ensure no defects like cracks, chips, oxidation, or coating issues.

Optimal Magnetization & Packaging: Magnets are evenly magnetized and arranged for efficient packaging and easy automation, tailored to your needs for top performance.

Advanced Packaging: Our multi-layer vacuum packaging, with moisture barriers and desiccants, protects against corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shockproof, moisture-resistant, and anti-magnetic leakage packaging meets international standards, complete with product lists, labels, and tracking codes for easy handling.

7.FAQ

Q. What are the main applications of roof-shaped neodymium magnets?

These magnets are used in a variety of applications, including sensors, motors, automation systems, and medical devices. Their unique shape and strong magnetic properties make them ideal for compact designs.

Q. Are the magnets customizable in terms of size and shape?

Yes, we offer full customization options for size, shape, and magnetic strength to meet specific customer requirements.

Q.What is the magnetization direction of these magnets?

The magnets can be magnetized axially, radially, or customized to suit your specific application.

8. Why Choose us ?

Dongguan Jinconn New Material Holdings Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

· High-Quality Products

We provide high-performance neodymium magnets with strict quality control, ensuring superior strength, reliability, and durability in every product.

· Customization Options

Our magnets are fully customizable, tailored to meet the specific needs of each customer, including unique sizes, shapes, and magnetization directions.

· Advanced Manufacturing Technology

With state-of-the-art equipment and production processes, we maintain consistency and precision, ensuring each batch of magnets meets the highest standards.

· Comprehensive Logistics Support

We offer efficient global logistics solutions, including customized packaging that ensures product safety during storage and shipping, with end-to-end tracking available.

9. Customization & Services

· Customized Magnet Sizes, Shapes, and Coatings: We offer fully tailored magnet dimensions, shapes, and coating options, including multiple layers, varying thicknesses, and color choices.

· Personalized Magnetization & Strength: Magnetization direction and field strength can be adjusted to meet your specific application requirements.

· Laser Engraving: We provide laser engraving services for logos, serial numbers, or other custom markings.

· Specialized Testing: We conduct packaging and suction force testing to ensure performance in unique or demanding applications.

Contact us to receive free samples and customized magnet solutions

Phone/WhatsApp/WeChat: +86 13829120676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat