Enhance your products or projects with our OR20mm x IR15mm x T60mm neodymium arc magnets. Ideal for mid-sized applications, theseheat resistant permanent high torque stable Nickel plating NdFeB rare earth Arc segment Magnets are perfect for electric motors, sensor assemblies, and rotary devices.

Permanent high torque Nickel plating NdFeB rare earth Arc segment Magnet

2025-7-11

1. Product Overview & Application Scenarios

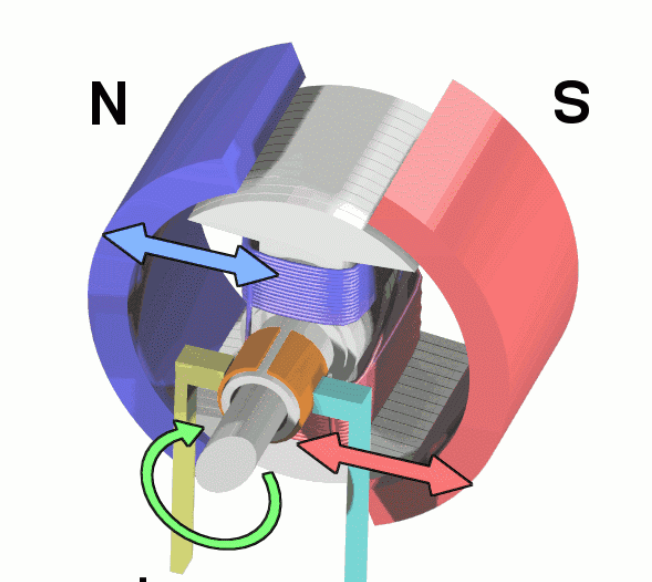

Enhance your products or projects with our OR20mm x IR15mm x T60mm neodymium arc magnets. Ideal for mid-sized applications, theseheat resistant permanent high torque stable Nickel plating NdFeB rare earth Arc segment Magnets are perfect for electric motors, sensor assemblies, and rotary devices. Their arc shape provides excellent magnetic flux distribution, enhancing the efficiency and accuracy of your engineering, manufacturing and energy-efficiency projects.

Please note: Ensure compatibility with your application by confirming the required dimensions. For applications requiring opposing poles, select arc magnets with the correct polarity orientation from our product range.

2. Technical Specifications

- Product Name: permanent high torque Nickel plating NdFeB rare earth Arc segment Magnet

- Magnet Grade: N35H (Br ≥11.8kGs, Hcj ≥17 kOe)

- Dimension: OR20mm x IR15mm x T60mm

- Dimensional Tolerance: +/-0.05

- Operating Temperature: ≤120°C (High-temp versions available)

- Density: ≥7.5 g/cm³

- Surface Magnetic Field: 3,300 Gs

- Magnetic Flux : 2.0 mWb (Fluxmeter-tested)

3. Surface Treatment & Coating Technology

To enhancethese tailor-made industrial grade permanent high torque Nickel plating NdFeB rare earth Arc segment Magnets’ corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

Edge Reinforcement: Laser cladding with nickel-based alloy at magnet seams (prevents electrochemical corrosion)

Edge Rounding: Reduces magnetic field distortion

Default Coating: Triple layer Ni-Cu-Ni (customizable)

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm)

Optional Coatings: Gold or silver plating for better conductivity and corrosion resistance

Coating Benefits:

Salt spray resistance and improved oxidation durability

Higher surface hardness and scratch resistance

Enhanced gloss, suitable for exposed parts

4. Appearance & Dimensional Inspection

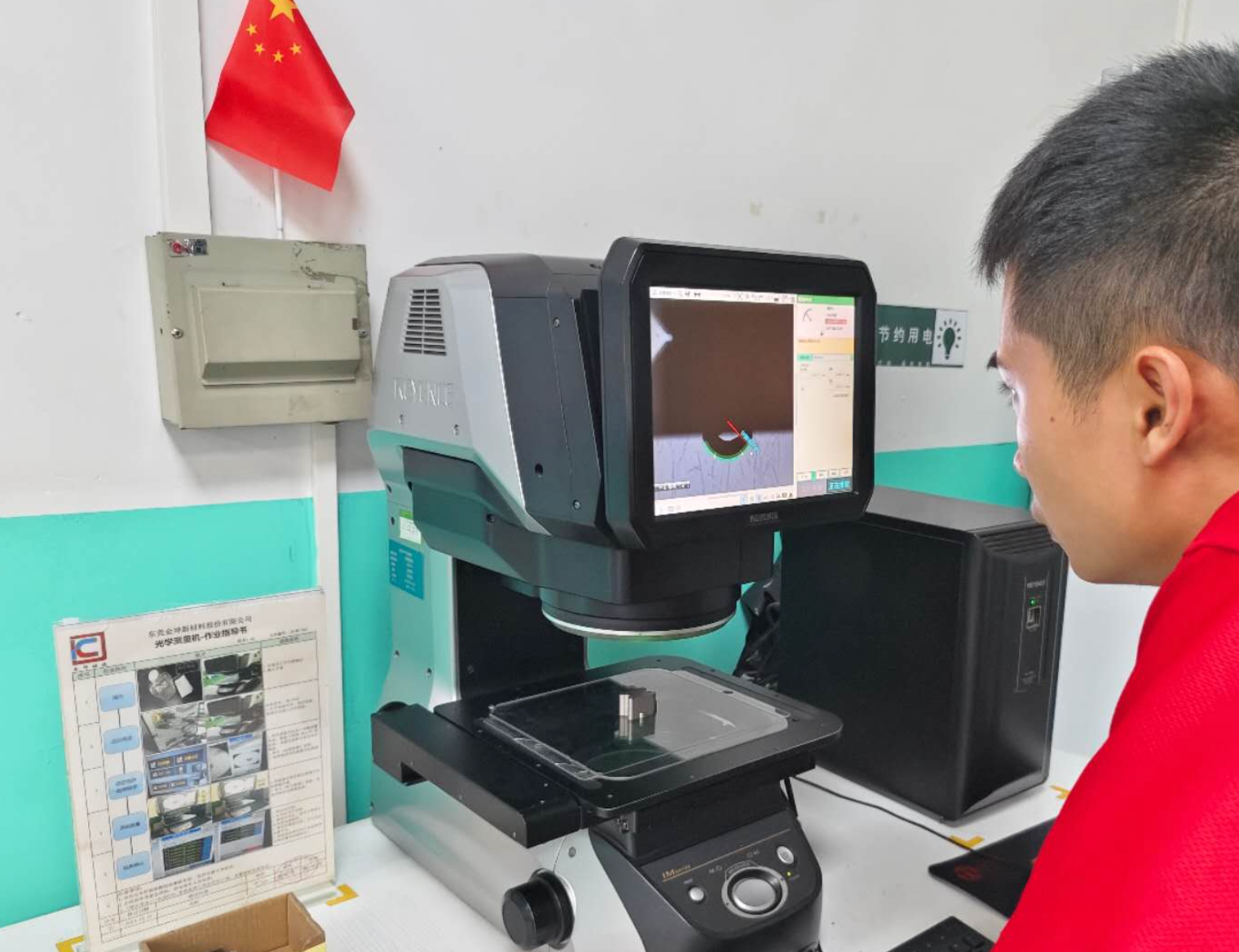

The ways of inspecting theseprofessional grade high remanence permanent high torque Nickel plating NdFeB rare earth Arc segment Magnets’ appearance are as following:

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Image Measurement System: High-definition cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

5. Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

6. Packaging & Transportation

Defect Elimination: 100% inspection using calipers, projectors, visual checks, and automated systems to reject cracked, chipped, oxidized, or coated-defective magnets.

Uniform Magnetization & Structured Arrangement: Magnets are uniformly magnetized and arranged for optimal packaging based on customer requirements to ensure performance and facilitate automated assembly.

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shock-proof, moisture-resistant, and anti-magnetic leakage packaging (e.g., multilayer cartons, plastic boxes, metal shielding) ensures compliance with international logistics standards. Each box includes a product list, labels, and tracking codes.

We understand logistics is more than just transport — it's about your commitment and customer satisfaction. Our solutions offer:

Global logistics support

End-to-end visual tracking

Multiple layers of transport safety

One-on-one customer service for tailored shipping plans

With our reliable land, sea, and air logistics network, we empower your business to go further and soar higher.

7. Usage Precautions?

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

8. Customization & Services

Custom magnet size, shape, and coating (layers, thickness, color)

Tailored magnetization direction and field strength

Laser engraving service for logos or serial numbers

Packaging and suction force testing for special applications

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

Phone/WhatsApp/WeChat: +8614716150318

Email: leo@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

.jpg)

Jinconn WeChat