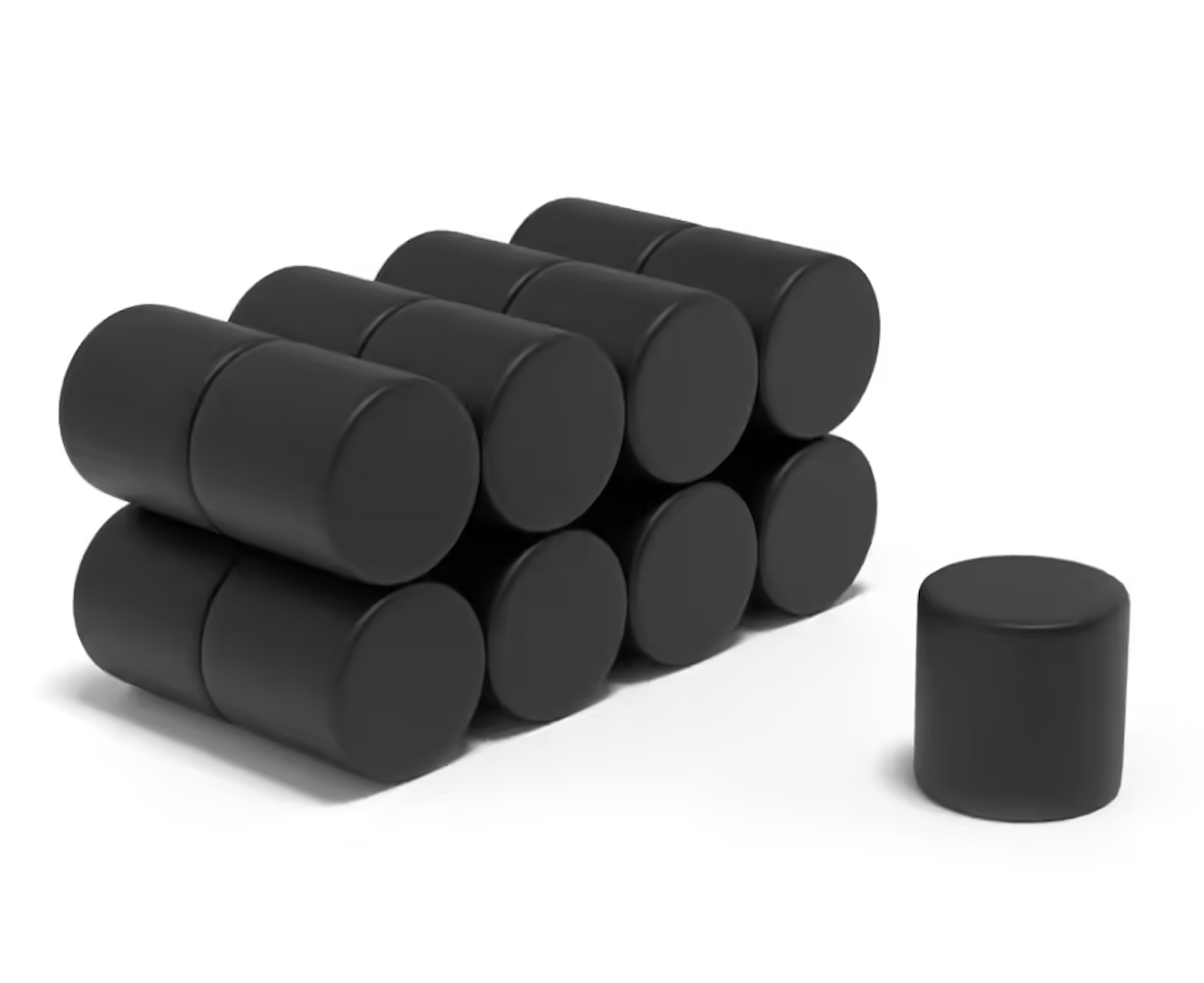

Precision customized thermal stable high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnet

1. Product Overview & Application Scenarios

These precision customized thermal stable energy efficient high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnets are excellent for a wide range of household and DIY applications, delivering powerful magnetic force in a slender, cylindrical form. They work perfectly for crafting custom magnetic latches, keeping cabinet doors firmly shut, or neatly arranging tools in confined areas, ensuring dependable performance for daily tasks. Beyond home use, these tailor made high adhesive force thermal stable high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnets are also commonly utilized in automotive engineering, especially in ABS sensors and fuel injection systems, where their elongated design guarantees accurate and stable magnetic fields. Their adaptability and high strength make them indispensable for both personal projects and industrial applications.

2. Technical Specifications

- Product Name: precision customized thermal stable high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnet

- Magnet Grade: N52 (Br ≥14.2 kGs, Hcj ≥12 kOe)

- Dimension: 20mm x 15mm

- Dimensional Tolerance: +/-0.05

- Operating Temperature: ≤80°C (High-temp versions available)

- Density: ≥7.5 g/cm³

- Surface Magnetic Field: 3,900 Gs

- Magnetic Flux : 2.0 mWb (Fluxmeter-tested)

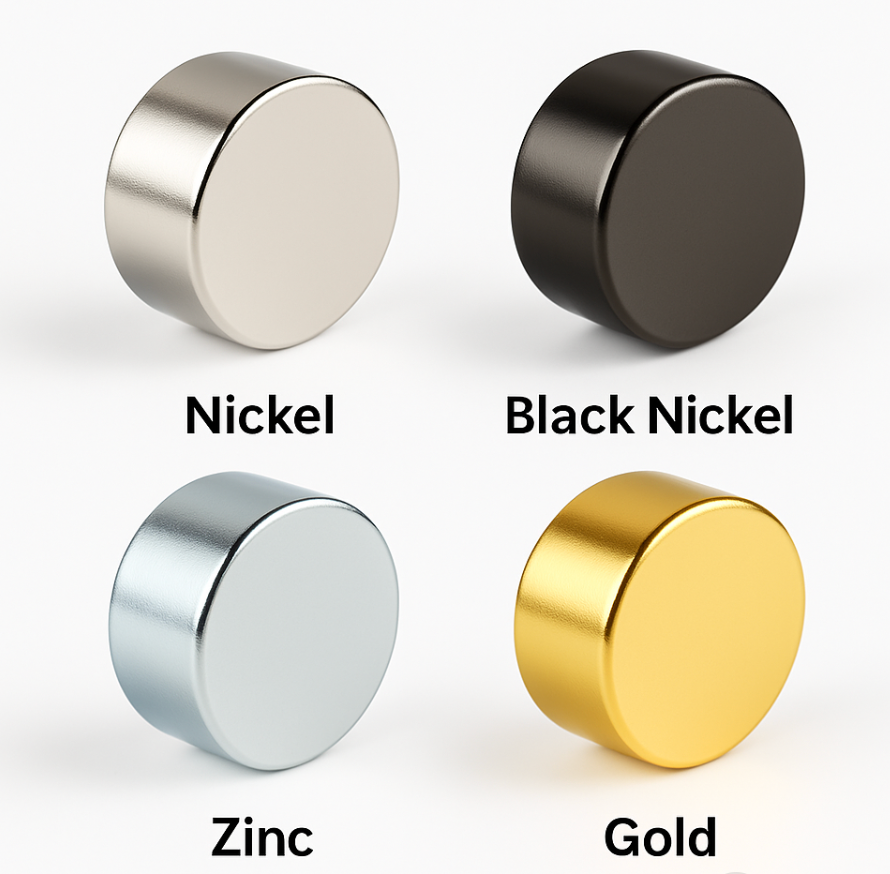

3. Surface Treatment & Coating Technology

To enhance this precision customized high torque thermal stable high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnet’s corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

Edge Reinforcement: Laser cladding with nickel-based alloy at magnet seams (prevents electrochemical corrosion)

Edge Rounding: Reduces magnetic field distortion

Default Coating: Triple layer Ni-Cu-Ni (customizable)

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm)

Optional Coatings: Gold or silver plating for better conductivity and corrosion resistance

Coating Benefits:

Salt spray resistance and improved oxidation durability

Higher surface hardness and scratch resistance

Enhanced gloss, suitable for exposed parts

4. Appearance & Dimensional Inspection

The ways of inspecting this precision customized thermal stable high remanence high pull force black epoxy coated compact Neodymium rare earth Cylinder Magnet’s apperance are as following:

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Image Measurement System: High-definition cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

5. Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

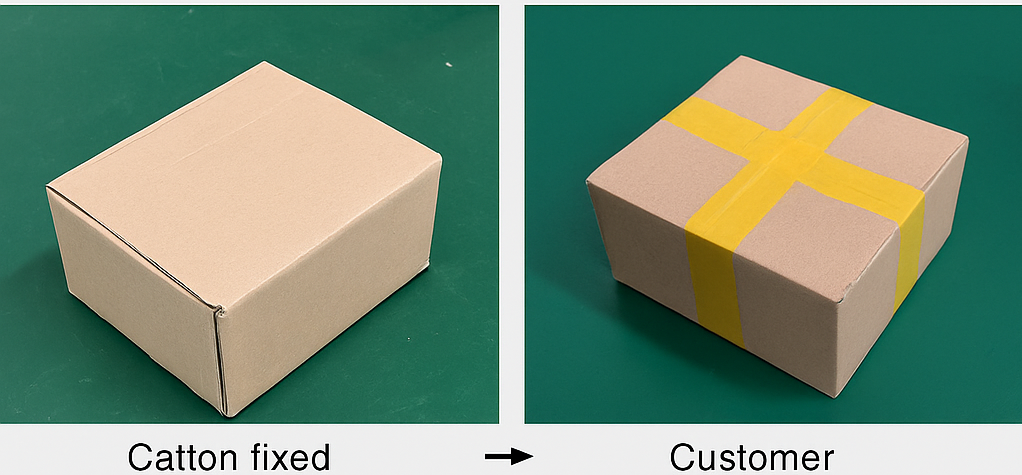

6. Packaging & Transportation

Defect Elimination: 100% inspection using calipers, projectors, visual checks, and automated systems to reject cracked, chipped, oxidized, or coated-defective magnets.

Uniform Magnetization & Structured Arrangement: Magnets are uniformly magnetized and arranged for optimal packaging based on customer requirements to ensure performance and facilitate automated assembly.

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shock-proof, moisture-resistant, and anti-magnetic leakage packaging (e.g., multilayer cartons, plastic boxes, metal shielding) ensures compliance with international logistics standards. Each box includes a product list, labels, and tracking codes.

We understand logistics is more than just transport — it's about your commitment and customer satisfaction. Our solutions offer:

Global logistics support

End-to-end visual tracking

Multiple layers of transport safety

One-on-one customer service for tailored shipping plans

With our reliable land, sea, and air logistics network, we empower your business to go further and soar higher.

8. Why Choose us ?

Dongguan Jinconn New Materials Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

✅ Rich Industry Experience

With over a decade of expertise in magnetic materials and precision magnet manufacturing, we understand the technical demands of a wide range of industries.

✅ Strong R&D and Customization Capabilities

Our in-house engineering and tooling teams enable us to offer custom-shaped, high-precision, and application-specific magnets tailored to your unique requirements.

9. Usage Precautions?

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10. Customization & Services

Custom magnet size, shape, and coating (layers, thickness, color)

Tailored magnetization direction and field strength

Laser engraving service for logos or serial numbers

Packaging and suction force testing for special applications

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

Phone/WhatsApp: +8614716150318

Email: leo@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat