D12 - D8mm x 2mm black epoxy coated Countersunk Hole Neodymium Disc Magnet

Epoxy Coated Countersunk Hole Neodymium Disc Magnet

These industrial use high remanence D12 - D8mm x 2mm Countersunk Hole Neodymium Disc Magnets

are easy to install and provide a strong magnetic hold, making them useful in a wide range of settings. In industrial environments, they’re often used to secure safety covers, fix metal plates in place, or hold components steady during use. Around the house, they work well for magnetic latches, organizing garage tools, or keeping heavy doors closed. In retail, these industrial use high remanence strong magnetic force fast response D12 - D8mm x 2mm Countersunk Hole Neodymium Disc Magnets are commonly used to mount signs and displays where strength and flexibility are important. Their durable design and wide range of uses make them a practical solution for many everyday tasks.

Magnet Grade: N40

N40 grade neodymium magnets offer a balanced combination of strength and versatility, with a maximum energy product of around 41 MGOe. Well-suited for various applications including motors, sensors, and precision assemblies, they deliver consistent magnetic performance. Their reliable field strength makes them a preferred choice for consumer electronics and technical equipment alike. Widely adopted across industries, N40 magnets are valued for their dependable and efficient performance.

Protective Coating: Epoxy

These industrial use high remanence heat resistant D12 - D8mm x 2mm Countersunk Hole Neodymium Disc Magnets offer enhanced protection against moisture, chemicals, and abrasion, making them ideal for demanding environments. The black epoxy layer forms a tough, non-metallic barrier that seals the magnet surface, preventing corrosion and wear over time. This coating is especially suited for outdoor use, humid conditions, or industrial settings where durability and long-term reliability are critical. In addition to their functional strength, the smooth matte finish provides a clean, modern look.

APPLICATION EXAMPLES

Material Neodymium (NdFeB)

Product Name: industrial use high remanence D12 - D8mm x 2mm Countersunk Hole Neodymium Disc Magnets

Magnetic Grade: N40 (Br ≥ 12.9 kGs, Hcj ≥ 14 kOe)

Thickness: D12-D 8mm x 2mm

Countersunk Hole: 3mm

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Magnetisation Direction: Axially Magnetised

Polarity: Countersunk Face North

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 3800 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.3 mWb (measured with fluxmeter)

Manufacturing Process

This industrial use high remanence corrosion resistant D12 - D8mm x 2mm Countersunk Hole Neodymium Disc Magnets is manufactured through the following key processes:

● A high-speed grinding wheel shapes the magnet's surfaces with tight dimensional tolerances.

● Coolant fluid is applied to control heat, reduce surface stress, and ensure a smooth finish.

● The result is a uniform, precisely dimensioned magnet with clean edges—ideal for high-performance applications.

This precision step is essential for ensuring that the final magnets meet strict quality standards for use in motors, sensors, electronics, and aerospace components

Surface Treatment & Plating

To enhance corrosion resistance and appearance:

Default Plating: Epoxy (customizable).

Standard Thickness: (10 - 20μm).

Features:

✔ Salt spray & oxidation resistance

✔ Increased surface hardness (scratch-resistant)

✔ Improved gloss (ideal for exposed components)

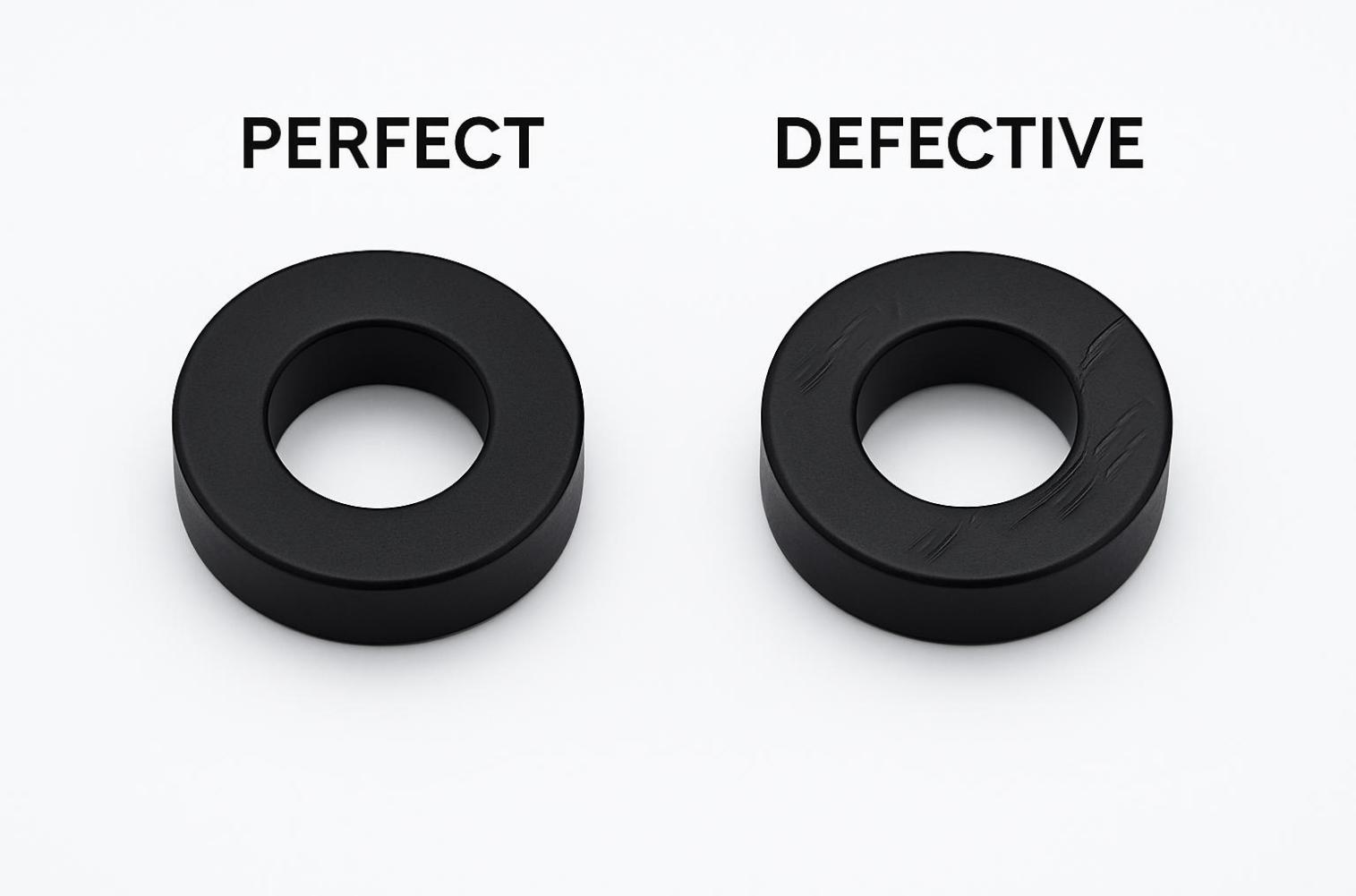

Appearance & Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation

Image Measurement System: High-res cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Magnetic Flux Consistency Test: Fluxmeters or Hall-effect testers measure magnetic flux across batches to ensure uniform performance in end-user applications.

Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

Applications

Electric Motors & Generators

Application: Precision-engineered magnets are employed in stators, rotors, and brushless DC motors to enhance magnetic flux density, efficiency, and torque performance.

Consumer Electronics

Application: High-performance neodymium magnets are integrated into speakers, haptic systems, vibration motors, and sensors, contributing to compact design and reliable functionality

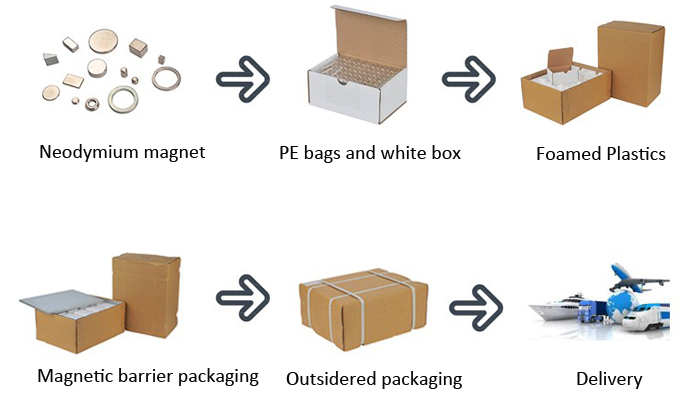

Packaging & Transportation

Defect Elimination: 100% inspection using calipers, projectors, visual checks, and automated systems to reject cracked, chipped, oxidized, or coated-defective magnets.

Uniform Magnetization & Structured Arrangement: Magnets are uniformly magnetized and arranged for optimal packaging based on customer requirements to ensure performance and facilitate automated assembly.

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shock-proof, moisture-resistant, and anti-magnetic leakage packaging (e.g., multilayer cartons, plastic boxes, metal shielding) ensures compliance with international logistics standards. Each box includes a product list, labels, and tracking codes.

Frequently Asked Questions:

Q: How to choose the correct magnetization direction?

Axial Magnetization: Magnetic lines flow through thickness — best for concentrated fields

Radial Magnetization: Magnetic lines radiate outward — for uniform field distribution

Multipole Magnetization: Multiple poles along circumference — for complex fields (e.g., motors, sensors)

Q: What is the maximum working temperature of a ring magnet?

Standard N-series: up to 80°C

High-temp grades (SH/UH/EH): up to 150°C–230°C

Dysprosium-enriched formulations can further enhance temperature resistance

Q: Does magnetism decay over time?

Under normal conditions (room temp, dry, no heavy vibration), NdFeB magnets exhibit excellent time stability (<5% loss over 10 years). However, factors like:

● Temperature overrun

● Strong external magnetic fields

● Surface corrosion

● Mechanical impact may affect performance.

With deep expertise in magnetic materials, we deliver solutions for industries like EVs, smart manufacturing, and electronics. Our strong technical capabilities and product consistency have earned the trust of customers worldwide.

Usage Precautions?

● Handle gently: Avoid impacts/drops (brittle material).

● Prevent pinching: Slide magnets apart—do not pry.

● Polarity check: Install correctly to avoid malfunctions.

● Avoid moisture/acids: Store in dry, mild environments.

● Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

Customization & Services

● Custom magnet size, shape, and coating (layers, thickness, color)

● Tailored magnetization direction and field strength

● Laser engraving service for logos or serial numbers

● Packaging and suction force testing for special applications

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

We’re here to help!

Phone/WhatsApp/WeChat:+86 180 3822 5893

Email: info@jinconn.com

Website: www.jinconnmagnet.com

Address: Xiaohe Industrial Zone, Daojia

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat