Engineered for precision and power, this custom-tailored compact size lightweight premium countersunk hole Neodymium magnet is crafted from premium-grade NdFeB (Neodymium Iron Boron), the most powerful commercially available magnetic material.

Customized compact size lightweight high performance premium countersunk Hole Neodymium Disc Magnet

1. Product Overview

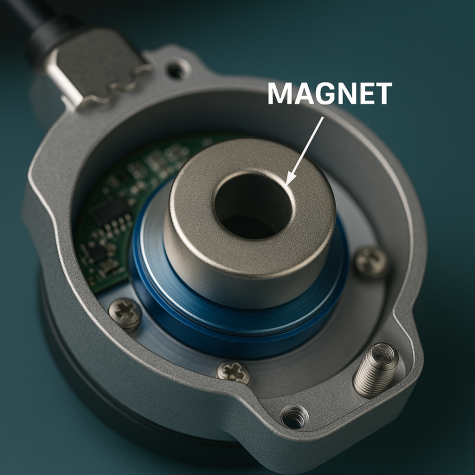

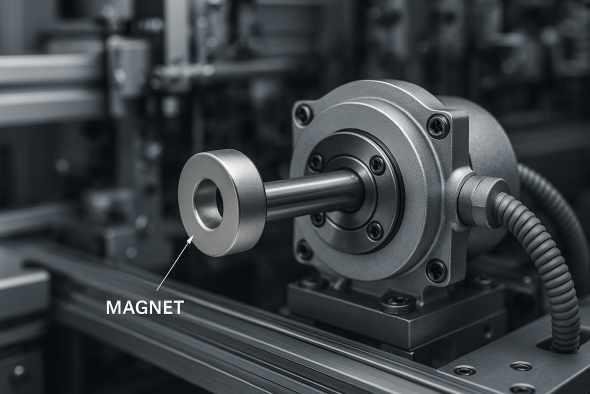

Engineered for precision and power, this custom-tailored compact size lightweight premium countersunk hole Neodymium magnet is crafted from premium-grade NdFeB (Neodymium Iron Boron), the most powerful commercially available magnetic material. With its central hole design, this ring magnet is ideal for applications requiring secure mounting, alignment, or rotational balance—perfect for motors, sensors, audio equipment, robotics, and automation systems.

Key Features & Advantages:

✅ Extreme Magnetic Strength

Manufactured with grades up to N52, delivering exceptional magnetic pull in compact dimensions.

✅ High Dimensional Precision

Machined to strict tolerances, ensuring stable performance and reliable integration into mechanical systems.

✅ Durable Surface Coating

Protected by a triple Ni-Cu-Ni plating, offering strong resistance to corrosion, oxidation, and wear—ideal for long-term use in both dry and humid environments.

✅ Efficient Mounting

The central bore allows for easy screw fixing, shaft alignment, or nesting, providing versatility across industrial and consumer applications.

✅ Wide Operating Range

Suitable for environments up to 80–200°C, depending on grade and coating, with low demagnetization loss over time.

2. Technical Parameters

- Product Name: Customized compact size lightweight high performance premium countersunk Hole Neodymium Disc Magnet

- Magnet Grade: N48 (Br ≥14.3 kGs, Hcj ≥ 10.8 KOe)

- Dimensions:Y20x10x5mm

- Tolerance: Length ±0.05 mm, Width ±0.05 mm, Thickness ±0.05 mm

- Operating Temperature: ≤ 80°C (High-temperature versions available)

- Density: ≥ 7.5 g/cm³

- Surface Magnetic Field: 2600-4200Gauss

- Magnetic Flux: 1.5-3.5mWb

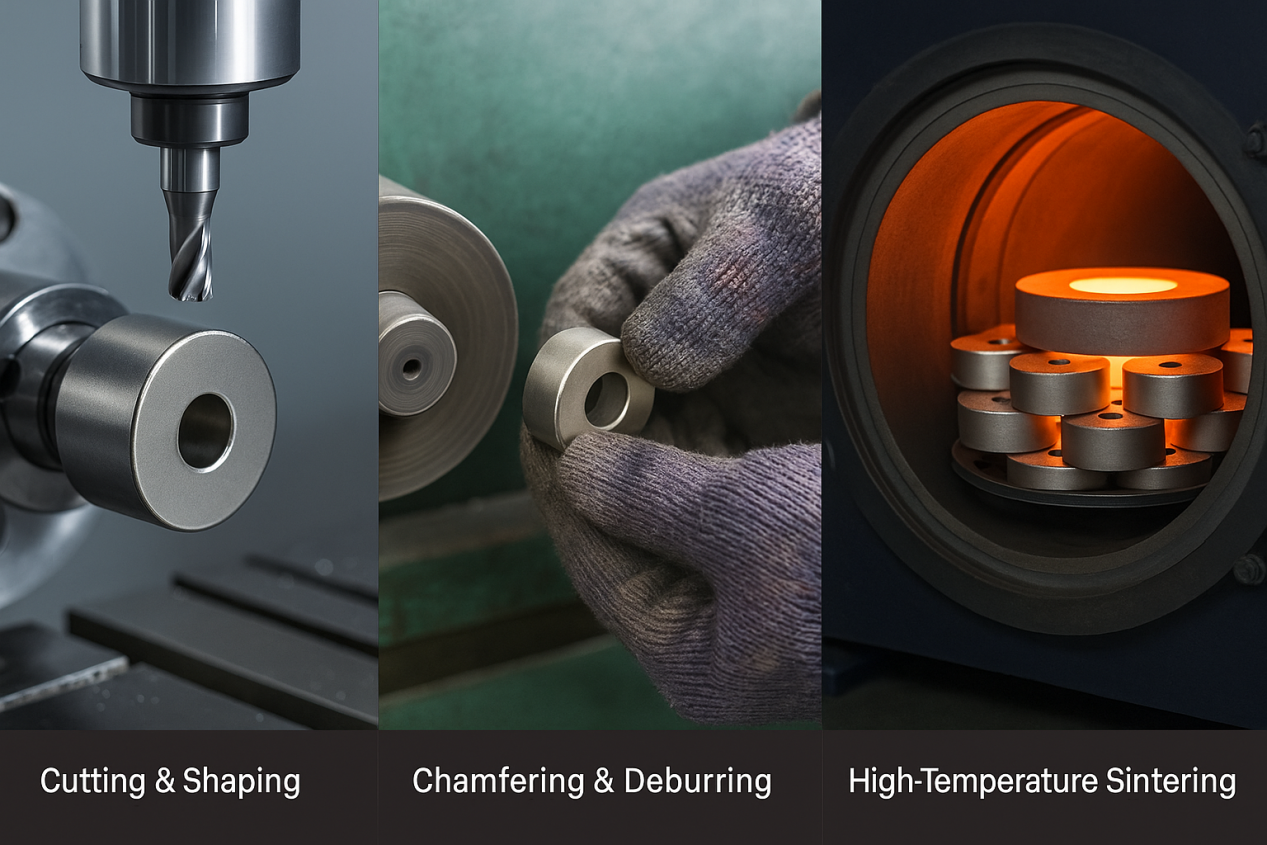

3. Manufacturing Process

This customized compact size high temperature resistance premium countersunk hole neodymium disc magnet through the following procedures :

- Cutting & Shaping: Precision cutting based on design drawings ensures standard cylindrical structure, with center drilling for uniformity and performance.

- Chamfering & Deburring: Edge chamfering and burr removal enhance safety and assembly precision.

- High-Temperature Sintering: Conducted in atmosphere-controlled furnaces for enhanced density, mechanical strength, and magnetic properties.

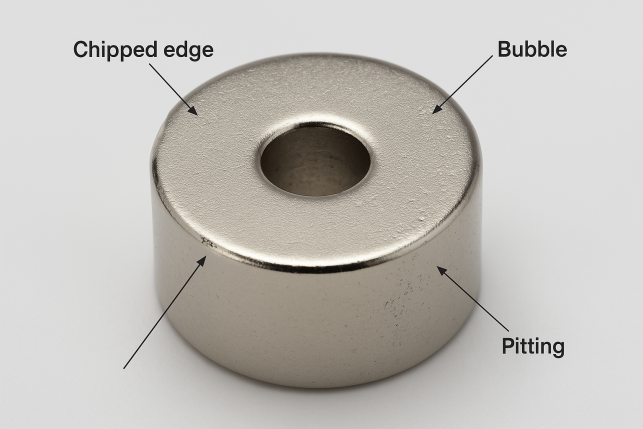

4. Appearance & Dimensional Inspection Standards

- Manual measurement with micrometers or calipers

- Visual inspection under 800–1200 lumens

- CCD intelligent sorting system for full inspection

5. Reliability Testing

This custom-tailored compact size lightweight heat resistance stable countersunk NdFeB magnet hole Neodymium magnet through the following reliability tests:

- Impact Testing and Vibration Testing: Simulate shocks and vibrations during transportation and usage to ensure the magnet's reliability in working environments.

- High-Temperature Demagnetization Testing: Verify the magnetic stability of the magnet under high-temperature conditions to ensure long-term performance consistency.

- Damp Heat Testing: Expose the magnet to high-humidity environments to examine its moisture resistance and anti-corrosion capabilities.

6. Packaging Process & Instructions

- Defective products are removed after full inspection

- Approved magnets are magnetized and arranged uniformly

- Packed in boxes with custom quantities and labeling

- Each unit is vacuum-packed with anti-magnetic shielding and shock-absorbing pads

- Small boxes are packed into larger cartons offering moisture, impact, and EMI protection

- Packaging customization available

6. Application Fields

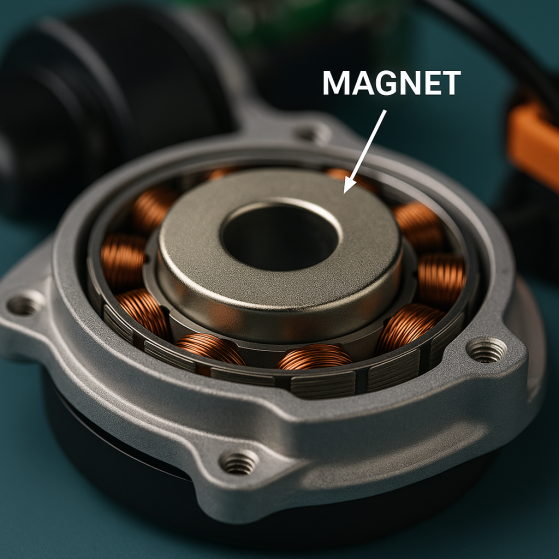

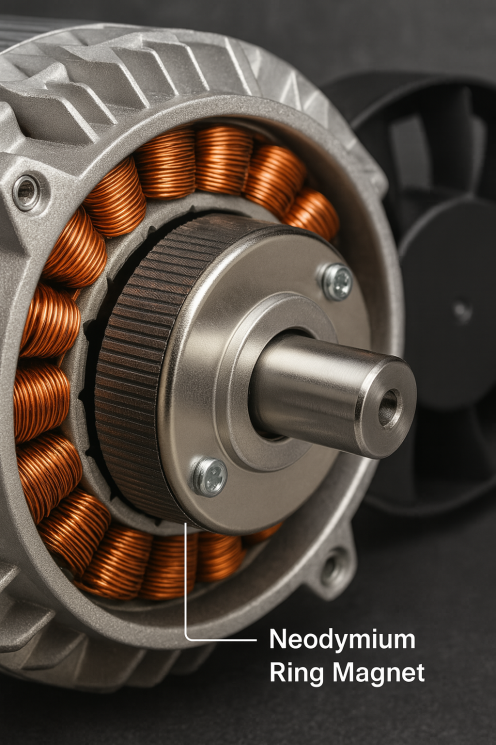

Motors & Generators

Applications: BLDC motors, servo motors, wind turbines, stepper motors, PMSMs

Benefits:

High magnetic flux for greater torque and smoother rotation

Central hole enables easy shaft mounting

Energy-efficient and thermally stable in demanding conditions

Sensors & Industrial Automation

Applications: Rotary and linear encoders, magnetic sensors, automation position detection

Benefits:

Consistent and focused magnetic field for precision sensing

Compact, integration-friendly design

High EMI resistance, suitable for harsh environments

Audio Devices & Acoustic Systems

Applications: Speakers, headphones, microphone magnetic systems

Benefits:

High-performance magnetic field enhances sound clarity and bass

Small size, strong force for compact design

Stable magnetism reduces harmonic distortion

Smart Home & Consumer Electronics

Applications: Smart locks, magnetic chargers, phone mounts, laptop hinge modules

Benefits:

Clean, reliable structure enhances product usability

Compatible with induction and proximity sensors

7. Usage Precautions?

● Handle gently: Avoid impacts/drops (brittle material).

● Prevent pinching: Slide magnets apart—do not pry.

● Polarity check: Install correctly to avoid malfunctions.

● Avoid moisture/acids: Store in dry, mild environments.

● Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

8. Customization & Services

● Custom magnet size, shape, and coating (layers, thickness, color)

● Tailored magnetization direction and field strength

● Laser engraving service for logos or serial numbers

● Packaging and suction force testing for special applications

9. Why Choose us ?

Dongguan Jinconn New Material Holdings Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

We’re here to help!

Phone/WhatsApp/WeChat:+86 180 3822 5893

Email: info@jinconn.com

Website: www.jinconnmagnet.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat