Designed for high-performance applications,customized premium quality high magnetic force heat resistance permanent stable small arc-shaped ndfeb Magnets play a vital role in modern motors and generators that demand precise magnetic positioning.

Customized premium quality high magnetic force permanent stable small arc-shaped ndfeb Magnet

Custom Shaped Neodymium Magnet

Designed for high-performance applications,customized premium quality high magnetic force heat resistance permanent stable small arc-shaped ndfeb Magnets play a vital role in modern motors and generators that demand precise magnetic positioning. Their unique form allows them to fit perfectly around components like rotors or stators, helping to maintain steady magnetic flow and support efficient energy conversion.

These precision customized premium quality high magnetic force corrosion resistance permanent stable small arc-shaped ndfeb Magnets are widely used in electric vehicles, wind turbines, and automated industrial systems—where strong, reliable magnetic performance is key. Built to deliver both power and precision, they help improve overall system efficiency, making them a smart choice for industries focused on innovation, sustainability, and performance.

Magnet Grade: N42

N42 grade neodymium magnets offer a balanced combination of strength and versatility, with a maximum energy product of around 42 MGOe. Well-suited for various applications including motors, sensors, and precision assemblies, they deliver consistent magnetic performance. Their reliable field strength makes them a preferred choice for consumer electronics and technical equipment alike. Widely adopted across industries, N42 magnets are valued for their dependable and efficient performance.

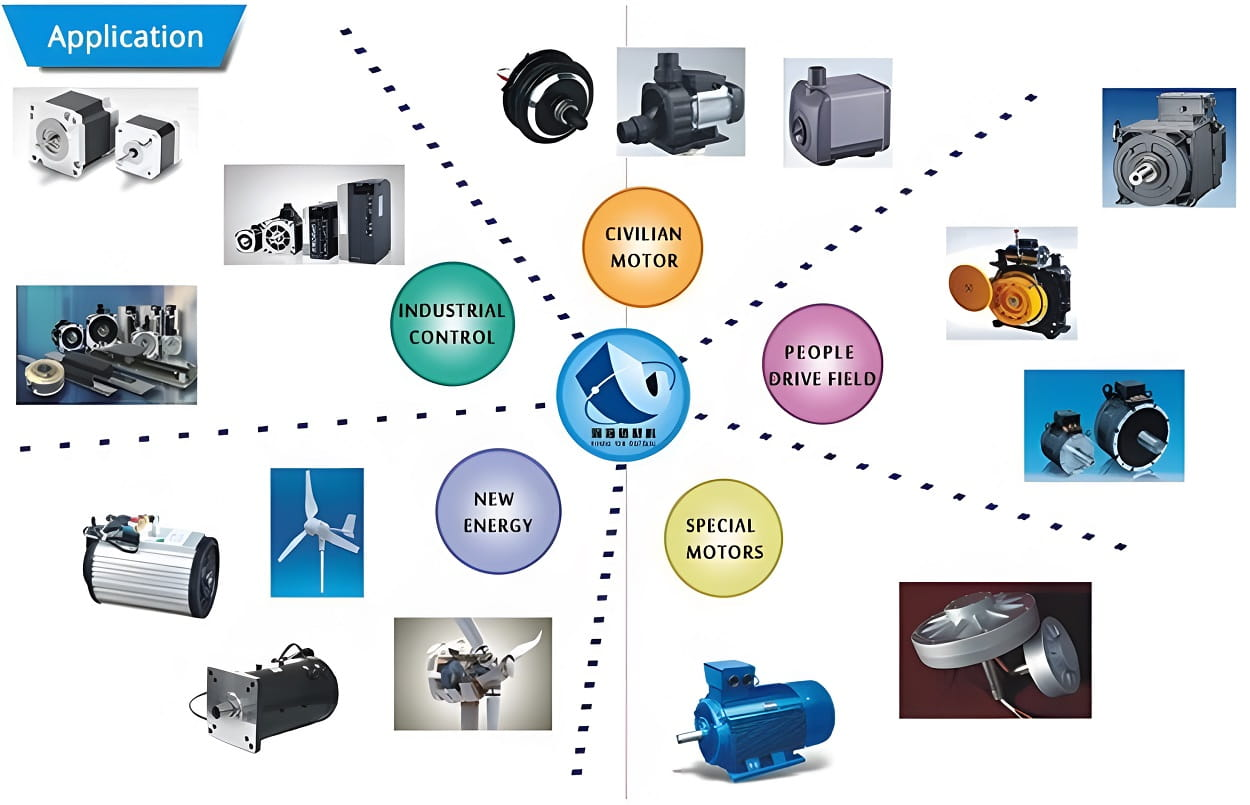

APPLICATION EXAMPLES

Material Neodymium (NdFeB)

Product Name: customized premium quality high magnetic force permanent stable small arc-shaped ndfeb Magnet

Magnetic Grade: N42 (Br ≥ 13.5 kGs, Hcj ≥ 12 kOe)

Thickness: L8mm x 3mm x 2mm

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

Magnetisation Direction: Axially Magnetised

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 3800 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.3 mWb (measured with fluxmeter)

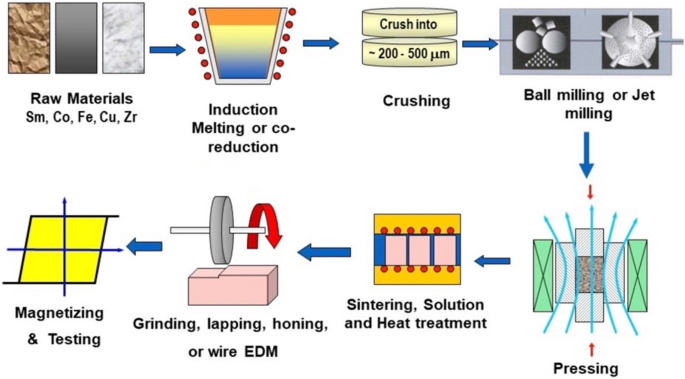

Manufacturing Process

This tailor-made premium quality powerful permanent stable small arc-shaped ndfeb Magnet is manufactured through the following key processes:

● A high-speed grinding wheel shapes the magnet's surfaces with tight dimensional tolerances.

● Coolant fluid is applied to control heat, reduce surface stress, and ensure a smooth finish.

● The result is a uniform, precisely dimensioned magnet with clean edges—ideal for high-performance applications.

This precision step is essential for ensuring that the final magnets meet strict quality standards for use in motors, sensors, electronics, and aerospace components

Surface Treatment & Plating

To enhance corrosion resistance and appearance:

Default Plating: Triple-layer Ni-Cu-Ni (customizable).

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm).

Optional Plating: Single-layer Zn (5μm) for cost-sensitive projects.

Features:

✔ Salt spray & oxidation resistance

✔ Increased surface hardness (scratch-resistant)

✔ Improved gloss (ideal for exposed components)

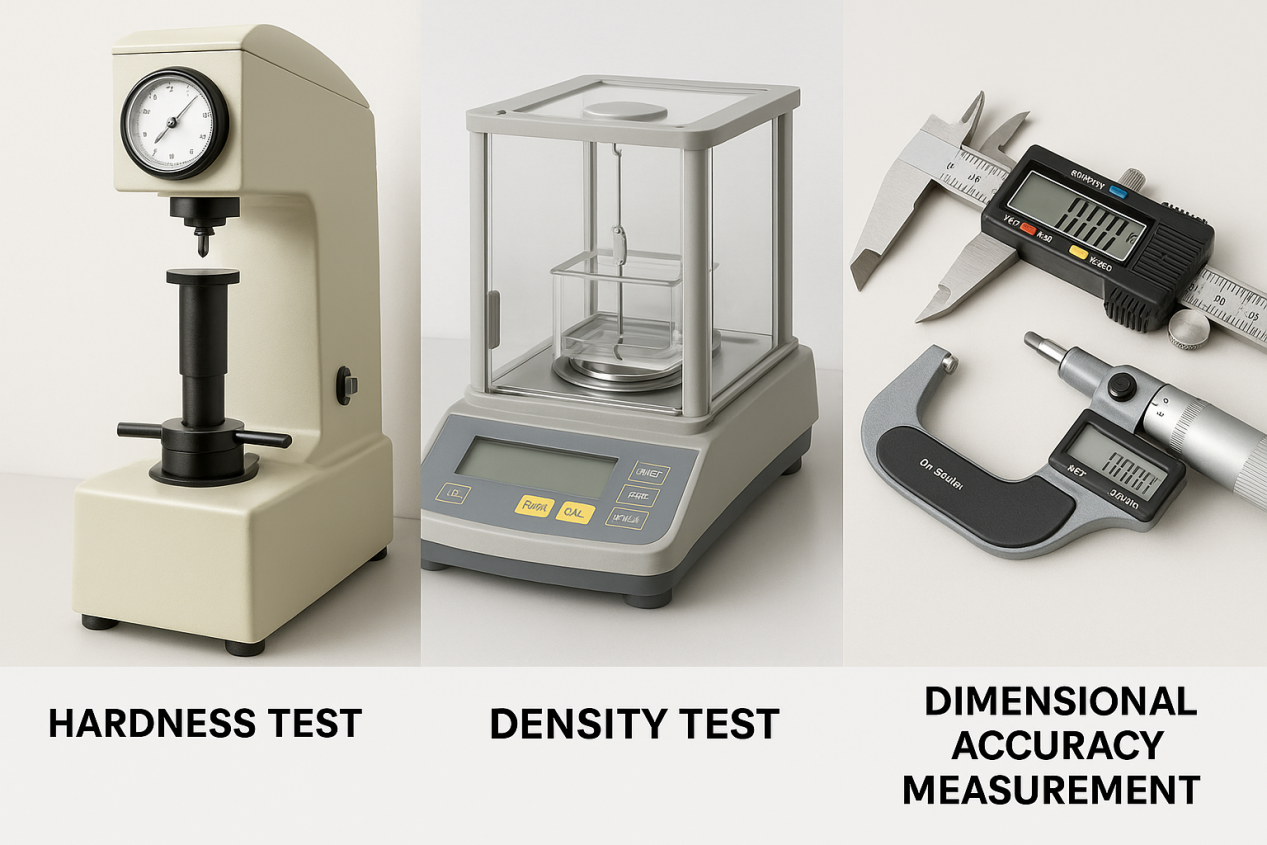

Appearance & Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation

Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

Damp Heat Test: Evaluates resistance to high humidity and corrosion.

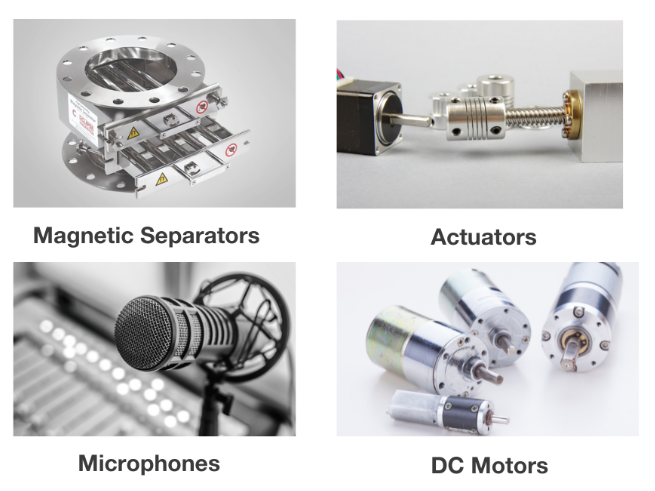

Applications

Electric Motors & Generators

Application: Precision-engineered magnets are employed in stators, rotors, and brushless DC motors to enhance magnetic flux density, efficiency, and torque performance.

Consumer Electronics

Application: High-performance neodymium magnets are integrated into speakers, haptic systems, vibration motors, and sensors, contributing to compact design and reliable functionality.

We understand logistics is more than just transport — it's about your commitment and customer satisfaction. Our solutions offer:

● Global logistics support

● End-to-end visual tracking

● Multiple layers of transport safety

● One-on-one customer service for tailored shipping plans

With our reliable land, sea, and air logistics network, we empower your business to go further and soar higher.

With deep expertise in magnetic materials, we deliver solutions for industries like EVs, smart manufacturing, and electronics. Our strong technical capabilities and product consistency have earned the trust of customers worldwide.

Usage Precautions?

● Handle gently: Avoid impacts/drops (brittle material).

● Prevent pinching: Slide magnets apart—do not pry.

● Polarity check: Install correctly to avoid malfunctions.

● Avoid moisture/acids: Store in dry, mild environments.

● Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

Customization & Services

● Custom magnet size, shape, and coating (layers, thickness, color)

● Tailored magnetization direction and field strength

● Laser engraving service for logos or serial numbers

● Packaging and suction force testing for special applications

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

We’re here to help!

Phone/WhatsApp/WeChat:+86 180 3822 5893

Email: info@jinconn.com

Website: www.jinconnmagnet.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Gu

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat