Compact neodymium cylinder magnet, nickel‑copper‑epoxy coated 10mm x 20mm (3mm hole) cylinder shape epoxy-coated neodymium magnets

Understanding Neodymium Magnets

These high-temperature, customised, industrial-strength quality, compact neodymium cylinder magnet, nickel‑copper‑epoxy coated, 10mm x 20mm (3mm hole) cylinder shape epoxy-coated neodymium magnets are known for their exceptional magnetic strength, making them the strongest type of permanent magnet on the market. Their compact size allows them to deliver high magnetic force even in space-constrained applications. In construction, they help securely position metal components during assembly, while in the medical sector, they play a vital role in the consistent performance of imaging systems and sensitive equipment. From everyday home tasks to demanding industrial operations, these magnets ensure dependable, long-lasting functionality.

Epoxy Coated Cylinder Shape Neodymium Magnet

These countersunk disc high-temperature, customised, industrial-strength quality, compact neodymium cylinder magnets, nickel‑copper‑epoxy coated, 10mm x 20mm (3mm hole) cylinder shape epoxy-coated neodymium magnets are easy to install and provide a strong magnetic hold, making them useful in a wide range of settings. In industrial environments, they’re often used to secure safety covers, fix metal plates in place, or hold components steady during use. Around the house, they work well for magnetic latches, organizing garage tools, or keeping heavy doors closed. In retail, they’re commonly used to mount signs and displays where strength and flexibility are important. Their durable design and wide range of uses make them a practical solution for many everyday tasks.

Magnet Grade: N42

N42 grade neodymium high-temperature, customised, industrial-strength quality, compact neodymium cylinder magnet, nickel‑copper‑epoxy coated, 10mm x 20mm (3mm hole) cylinder shape epoxy-coated neodymium magnets offer a balanced combination of strength and versatility, with a maximum energy product of around 42 MGOe. Well-suited for various applications, including motors, sensors, and precision assemblies, they deliver consistent magnetic performance. Their reliable field strength makes them a preferred choice for consumer electronics and technical equipment alike. Widely adopted across industries, N42 magnets are valued for their dependable and efficient performance.

Protective Coating: Epoxy

These epoxy-coated neodymium magnets offer enhanced protection against moisture, chemicals, and abrasion, making them ideal for demanding environments. The black epoxy layer forms a tough, non-metallic barrier that seals the magnet surface, preventing corrosion and wear over time. This coating is especially suited for outdoor use, humid conditions, or industrial settings where durability and long-term reliability are critical. In addition to their functional strength, the smooth matte finish provides a clean, modern look.

APPLICATION EXAMPLES

Material Neodymium (NdFeB)

Product Name: Compact neodymium cylinder magnet, nickel‑copper‑epoxy coated 10mm x 20mm (3mm hole) cylinder shape epoxy-coated neodymium magnets

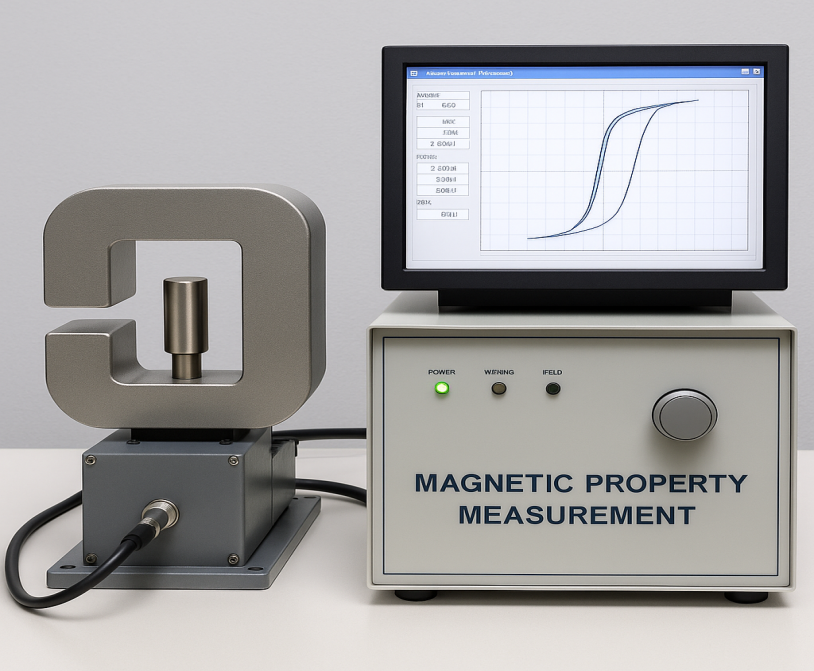

Magnetic Grade: N42 (Br ≥ 13.5 kGs, Hcj ≥ 12 kOe)

Thickness: D 10mm x 20mm

Countersunk Hole: 3mm

Dimensional Tolerance: Length ±0.05mm, Width ±0.05mm, Thickness ±0.05mm

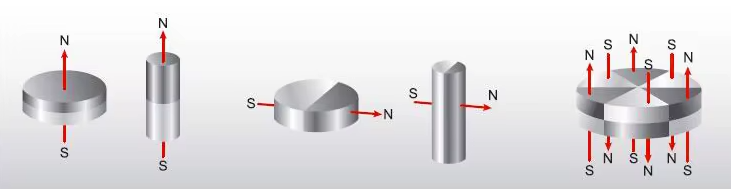

Magnetisation Direction: Axially Magnetised

Polarity: Countersunk Face North

Operating Temperature: ≤80°C (high-temp version available)

Density: ≥7.5 g/cm³

Surface Magnetic Field: 3800 ±200 Gauss (measured with TM-801 Gauss meter)

Magnetic Flux: 2.3 mWb (measured with fluxmeter)

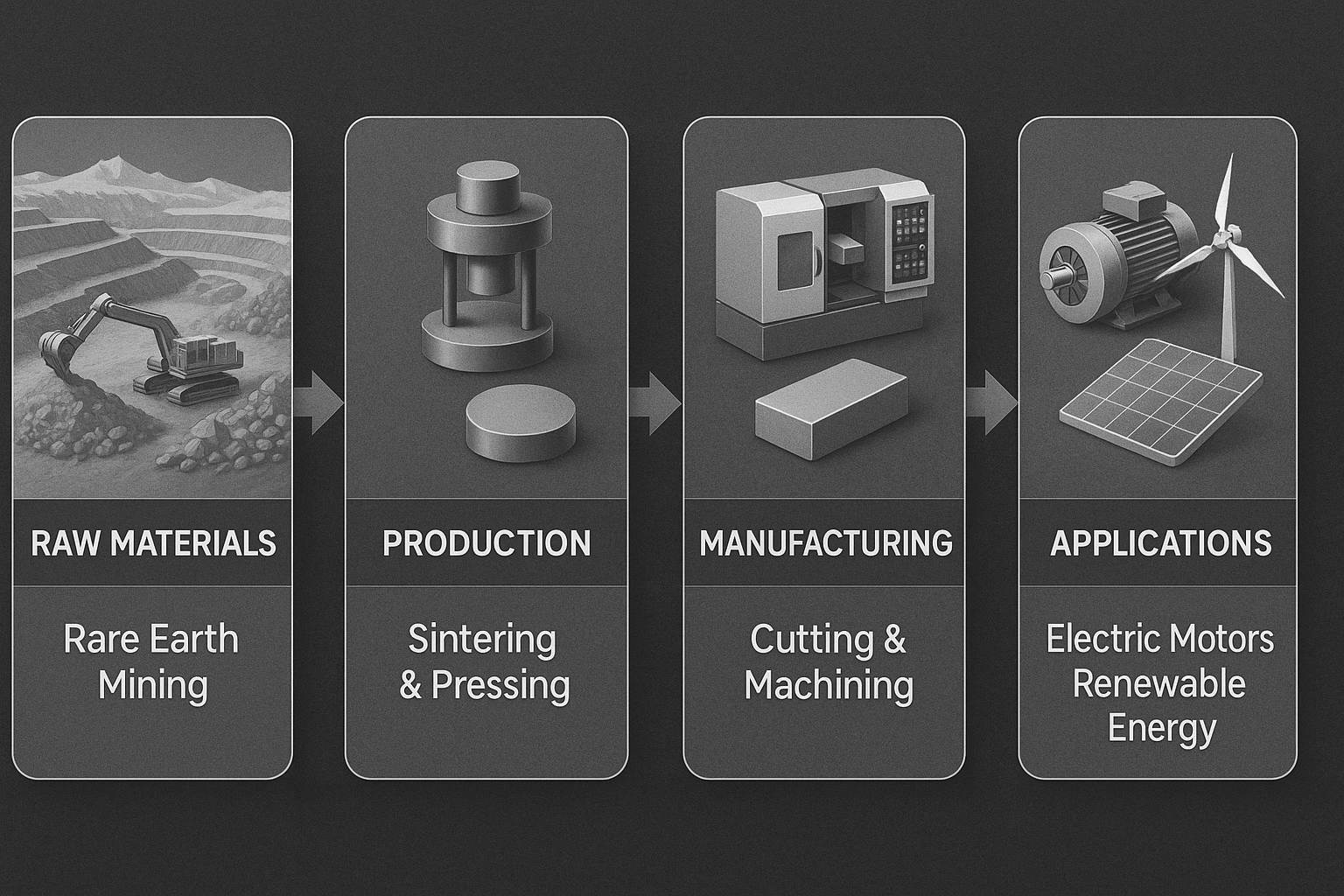

Manufacturing Process

The manufacturing process of this Precision customized strong magnetic force high energy density compact bore magnetic pot ndfeb magnet are as following:

Professional pulse magnetization equipment is used to inject strong and stable magnetic fields, ensuring the magnet meets design specifications and performs reliably under high load or high-frequency operation.

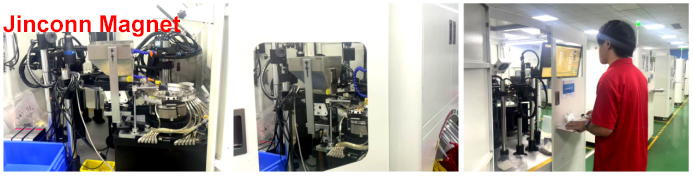

Appearance & Dimensional Inspection

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation

Image Measurement System: High-res cameras and algorithms conduct non-contact 2D measurements, especially for complex or irregular shapes, ensuring efficiency and objectivity in mass production.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

Reliability Testing

To ensure magnet maintain excellent corrosion resistance in complex or harsh environments, the salt spray test is an essential accelerated aging method. It simulates long-term exposure to marine climates, industrial pollution, humidity, or acidic and alkaline conditions, allowing for a reliable evaluation of the protective performance and durability of the magnet's surface coating.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

Packaging & Transportation

Defect Elimination: 100% inspection using calipers, projectors, visual checks, and automated systems to reject cracked, chipped, oxidized, or coated-defective magnets.

Uniform Magnetization & Structured Arrangement: Magnets are uniformly magnetized and arranged for optimal packaging based on customer requirements to ensure performance and facilitate automated assembly.

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shock-proof, moisture-resistant, and anti-magnetic leakage packaging (e.g., multilayer cartons, plastic boxes, metal shielding) ensures compliance with international logistics standards. Each box includes a product list, labels, and tracking codes.

We know logistics is more than moving goods — it’s about delivering your promise. Our trusted solutions offer:

Global shipping coverage

Real-time tracking from origin to destination

Enhanced safety at every stage

Dedicated service with customized shipping plans

With our robust land, sea, and air network, your business moves faster, safer, and with complete confidence.

Why Choose us ?

Dongguan Jinconn New Material Holdings Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

20+ years of magnet manufacturing expertise

Strict quality control & customization capability

Multilingual technical support with global delivery

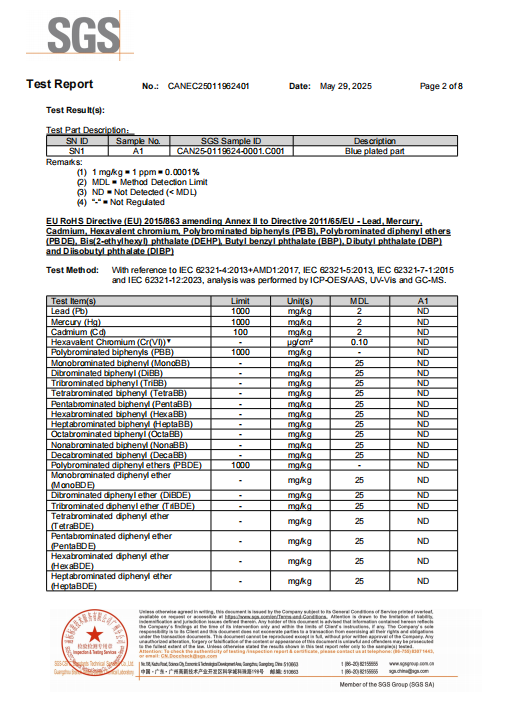

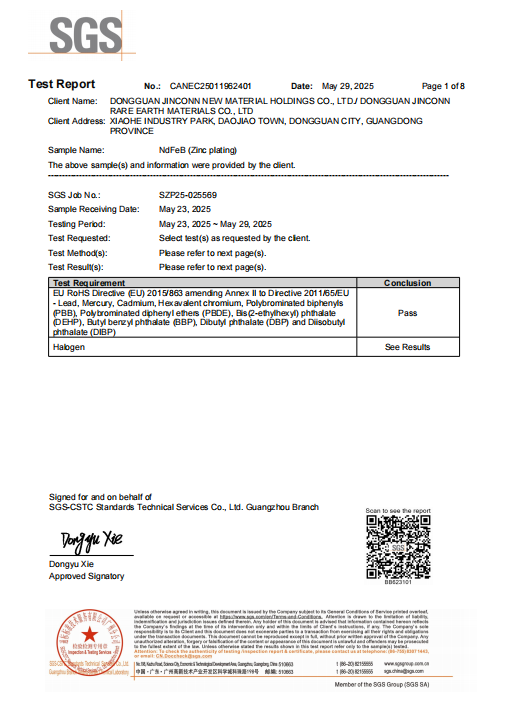

RoHS and REACH compliant

Please contact us for free samples, magnet customization solutions, and MSDSRoHS, ISO 9001, QC080000, IATF 16949, ISO 14001, ISO 27001 or other relevant certificates!

Usage Precautions?

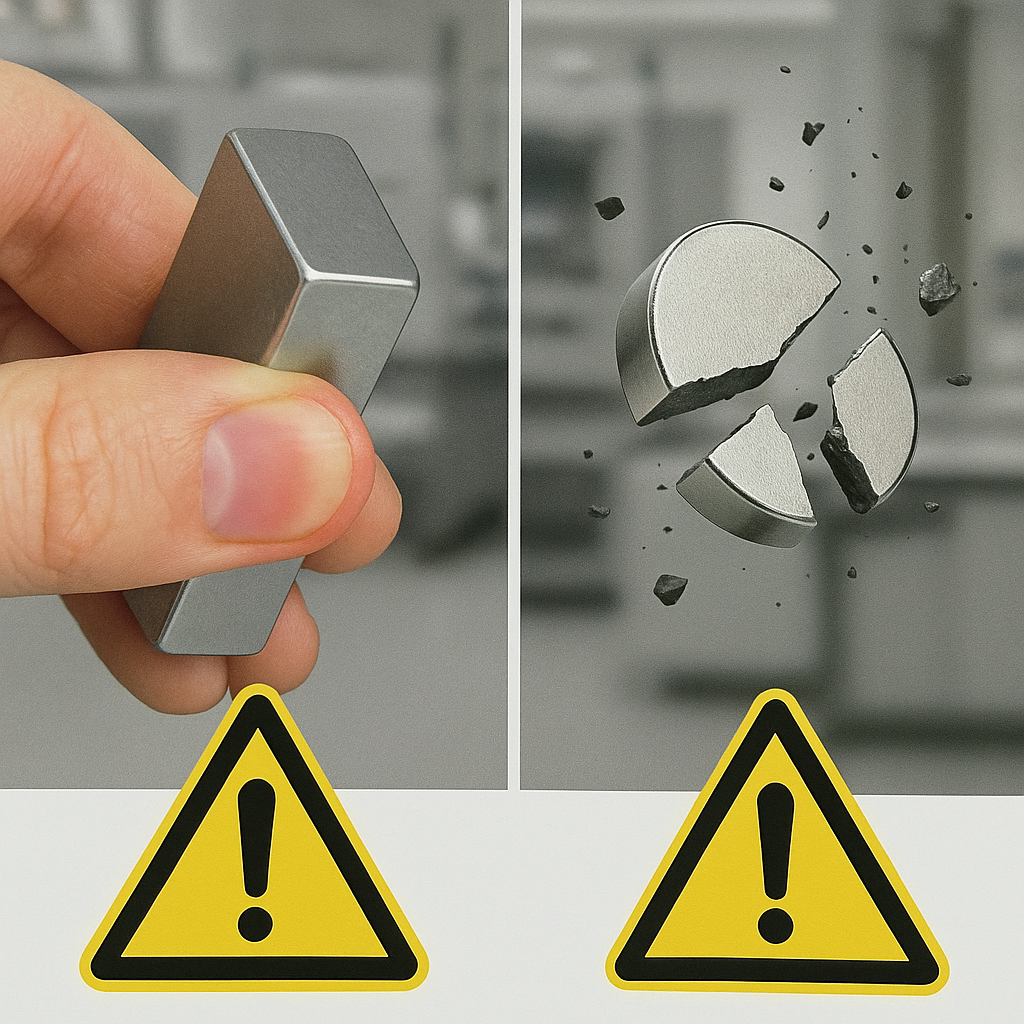

⚠ Safety & Handling Guidelines

Handle with care: Neodymium magnets are brittle and can chip or crack if dropped or impacted.

Avoid injury: Always slide magnets apart—do not force or pry them to separate.

Check polarity before use: Incorrect installation may cause malfunction or damage to equipment.

Store properly: Keep in a dry, neutral environment; avoid contact with moisture, acids, or corrosive substances.

Keep away from sensitive electronics: Do not place near hard drives, magnetic cards, pacemakers, or similar devices.

Customization & Services

Customizable magnet dimensions, geometry, and surface coatings (including layer count, thickness, and color)

Precision magnetization orientation and adjustable magnetic field intensity

Optional laser marking for logos, part numbers, or traceability codes

Specialized packaging and pull-force testing tailored to your application needs

With deep expertise in magnetic materials, we deliver solutions for industries like EVs, smart manufacturing, and electronics. Our strong technical capabilities and product consistency have earned the trust of customers worldwide.

Contact Us:

Phone/WhatsApp/WeChat: +86 13829120676

Email: Info@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Jinconn WeChat