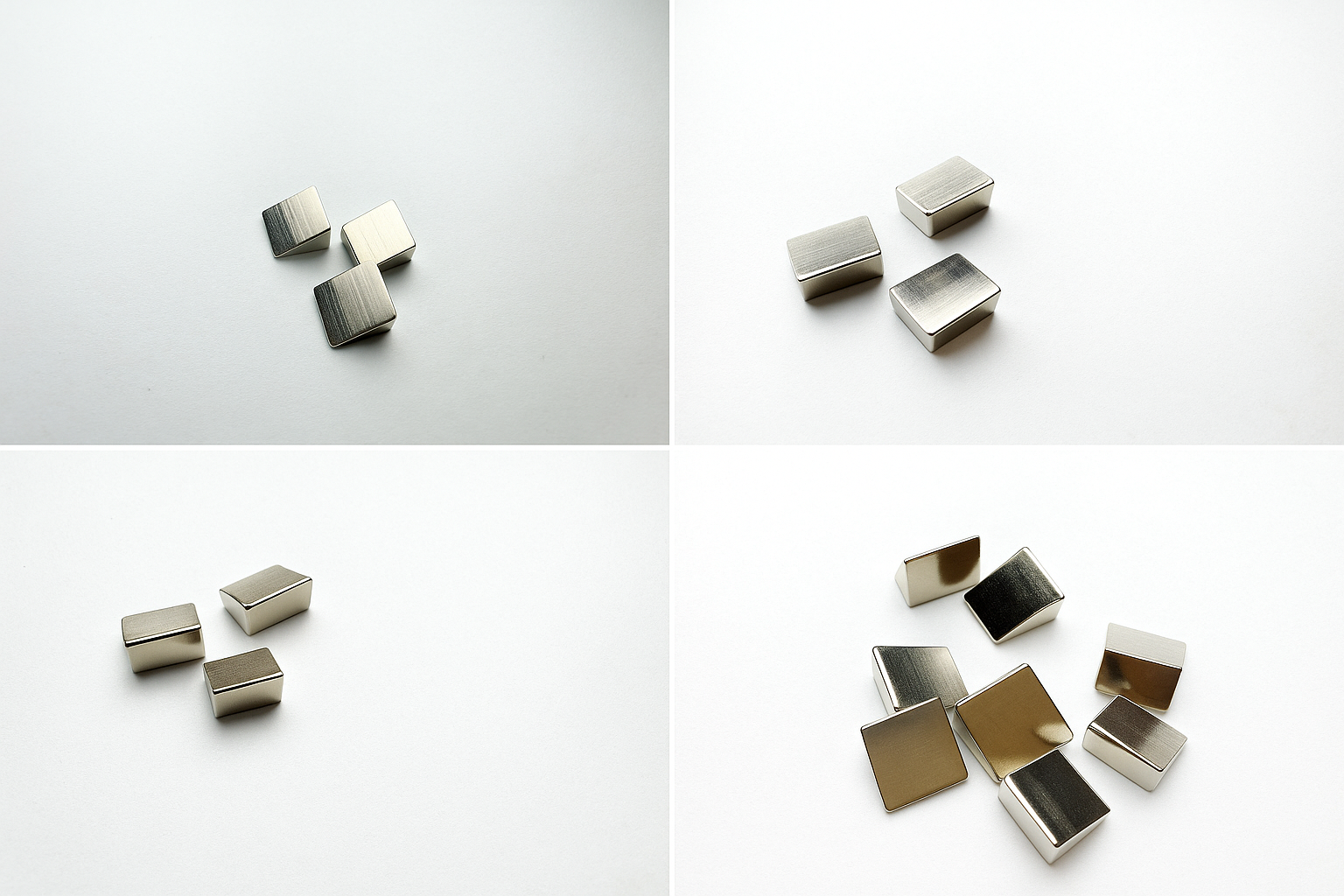

The magnets in the image are rectangular block magnets, more precisely, they are rectangular cuboid-shaped magnets. These heat resistant strong magnetic force high flux compact Neodymium block Rectangular Cuboid-Shaped Magnets have six flat faces, eight corners, and twelve edges, with slightly chamfered edges.

High flux compact Neodymium block Rectangular Cuboid-Shaped Magnet

2025-7-15

1. Product Overview & Application Scenarios

The magnets in the image are rectangular block magnets, more precisely, they are rectangular cuboid-shaped magnets. These heat resistant strong magnetic force high flux compact Neodymium block Rectangular Cuboid-Shaped Magnets have six flat faces, eight corners, and twelve edges, with slightly chamfered edges. These magnets are commonly used for:

- Woodworking jigs and fixtures

- Tool positioning

- Model assembly

- DIY magnetic installations around the home

This shape is convenient for embedding into wood or plastic structures, offering strong and stable magnetic force. The material is usually neodymium (NdFeB), and the surface is typically nickel-coated to prevent corrosion.

2. Technical Specifications

- Product Name: High flux compact Neodymium block Rectangular Cuboid-Shaped Magnet

- Magnet Grade: N52 (Br ≥14.2 kGs, Hcj ≥12 kOe)

- Dimension: Y5*4*3

- Dimensional Tolerance: +/-0.05

- Operating Temperature: ≤80°C (High-temp versions available)

- Density: ≥7.5 g/cm³

- Surface Magnetic Field: 1,800 Gs

- Magnetic Flux : 2.0 mWb (Fluxmeter-tested)

3. Surface Treatment & Coating Technology

To enhance these premium quality tight tolerance high flux compact Neodymium block Rectangular Cuboid-Shaped Magnets’ corrosion resistance, surface quality, and magnetic stability, the following treatments are used:

Edge Reinforcement: Laser cladding with nickel-based alloy at magnet seams (prevents electrochemical corrosion)

Edge Rounding: Reduces magnetic field distortion

Default Coating: Triple layer Ni-Cu-Ni (customizable)

Standard Thickness: Ni (3μm) + Cu (5μm) + Ni (4μm)

Optional Coatings: Gold or silver plating for better conductivity and corrosion resistance

4. Appearance & Dimensional Inspection

The ways of inspecting these professional grade high torque fast response high flux compact Neodymium block Rectangular Cuboid-Shaped Magnets’ appearance are as following:

Visual Inspection: Under standardized lighting, trained QC staff check for cracks, chipping, inclusions, pores, or oxidation.

Automated Intelligent Inspection: High-speed cameras with AI algorithms detect and reject defects (e.g., cracks, scratches, discoloration) and dimensional anomalies, improving yield and reducing human error.

Magnetic Flux Consistency Test: Fluxmeters or Hall-effect testers measure magnetic flux across batches to ensure uniform performance in end-user applications.

5. Reliability Testing

Impact & Vibration Test: Simulates shipping and usage conditions to ensure operational stability.

Constant Temperature & Humidity Test: Performed under 85°C and 85% RH for 96–500 hours. Performance and appearance are compared before and after testing.

Damp Heat Test: Evaluates resistance to high humidity and corrosion.

6. Packaging & Transportation

Defect Elimination: 100% inspection using calipers, projectors, visual checks, and automated systems to reject cracked, chipped, oxidized, or coated-defective magnets.

Uniform Magnetization & Structured Arrangement: Magnets are uniformly magnetized and arranged for optimal packaging based on customer requirements to ensure performance and facilitate automated assembly.

Vacuum Sealed Packaging: Multi-layer vacuum sealing with moisture barriers, desiccants or nitrogen, prevents corrosion and magnetic interference during storage and shipping.

Customized Outer Packaging: Shock-proof, moisture-resistant, and anti-magnetic leakage packaging (e.g., multilayer cartons, plastic boxes, metal shielding) ensures compliance with international logistics standards. Each box includes a product list, labels, and tracking codes.

7. FAQ

Q: How to choose the correct magnetization direction?

Axial Magnetization: Magnetic lines flow through thickness — best for concentrated fields

Radial Magnetization: Magnetic lines radiate outward — for uniform field distribution

Multipole Magnetization: Multiple poles along circumference — for complex fields (e.g., motors, sensors)

Q: What is the maximum working temperature of a ring magnet?

Standard N-series: up to 80°C

High-temp grades (SH/UH/EH): up to 150°C–230°C

Dysprosium-enriched formulations can further enhance temperature resistance

Q: Does magnetism decay over time?

Under normal conditions (room temp, dry, no heavy vibration), NdFeB magnets exhibit excellent time stability (<5% loss over 10 years). However, factors like:

Temperature overrun

Strong external magnetic fields

Surface corrosion

Mechanical impact may affect performance.

8. Why Choose us ?

Dongguan Jinconn New Materials Holdings Co., Ltd. is a publicly listed enterprise offering integrated R&D, manufacturing, and sales of rare earth magnets. Based in Xiaohe Industrial Zone, Daojiao Town, Dongguan, we serve clients across China and globally.

With deep expertise in magnetic materials, we deliver solutions for industries like EVs, smart manufacturing, and electronics. Our strong technical capabilities and product consistency have earned the trust of customers worldwide.

9. Usage Precautions?

Handle gently: Avoid impacts/drops (brittle material).

Prevent pinching: Slide magnets apart—do not pry.

Polarity check: Install correctly to avoid malfunctions.

Avoid moisture/acids: Store in dry, mild environments.

Keep away from sensitive devices: Hard drives, IC cards, pacemakers, etc.

10. Customization & Services

Custom magnet size, shape, and coating (layers, thickness, color)

Tailored magnetization direction and field strength

Laser engraving service for logos or serial numbers

Packaging and suction force testing for special applications

Contact Us

Phone/WhatsApp/WeChat: +8614716150318

Email: leo@jinconn.com

Address: Xiaohe Industrial Zone, Daojiao Town, Dongguan City, Guangdong Province, China

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

.jpg)

Jinconn WeChat